Leaderboard

Popular Content

Showing content with the highest reputation on 01/09/18 in all areas

-

Can you imagine the ad for the job? Must look like Paul McCartney. Must be willing to be shot.6 points

-

I picked this up yesterday. It’s Charvel 1B from 1987 and considering its age, it’s in super overall condition. I was never brave enough and far too cool to own one of these when they were popular, but now I’m older and no longer give a stinky poo, it’s the perfect time to have one! My poor band may think otherwise. I forgot just how good these bolt on Charvel necks are: it’s incredibly comfortable and I’ve been able to get a seriously low action on it. It also doh said great too and the reverse P pickup is a great variation. Now, where’s my hairspray?3 points

-

Hello! Thanks for having me. I’m hoping to learn from you all and share whatever I can! Briefly, I am a guitarist primarily (I have joined guitarchat), but I also play bass; I teach both. I have spent most of the last six weeks feeding my desire to learn more about the wonderful bass (it’s sooo much fun!!!). I’ve been enjoying Jamiroquai and Incognito, Zander Zon and Michael Manring; and have been working my way through the James Jamerson transcriptions and the Stuart Clayton Ultimate Slap books. Sat on the bass pile of books is the John Goldsby “The Jazz Bass Book” and another Stuart Clayton “Solo Arrangements....”. I can’t wait to get into them but life and the new term will probably get in the way! I’m also waiting for my new TC Electronic BH250 and Eden EX112 to arrive. My main bass is the Peavey Grind 6, which I hope to mod with the help of Ricardo Westie (he’s on here somewhere). I hope I’ve got this right, I’m not good with technology....it doesn’t have the right kind of strings!3 points

-

OK - this is where I have to repeat the warning to folks who may not have seen my other builds - and especially any 'beginner' builders. It is simply this. My threads describe how I personally go about things - and sometimes they work and sometimes they don't. Generally I detail both. They are statements of how I have done things but are never - and will never be - statements of 'this is how it should be done.' I am essentially a bedroom builder and quite often - through necessity or because I have difficulties with the way most builders do things - I go about things differently to the 'conventional' way. When they work, no one is more surprised than me . So by all means try things the same way if you think that it will work in your particular situation - but please NEVER assume I know what I'm doing! So Ironing on binding. (See what I mean ) I've got to that age where I forget things - and when I did the binding for the top, I had forgotten that I once did binding a different way which suited me much, much better. Those of you who have followed any of my veneering threads (or saw my demo at the last Midlands Bass Bash) know that I use Evostick wood glue as an iron-on adhesive. And I tried it once on binding. So here goes again! Basically - other than the iron and a pair of gloves - this is the kit. No bicycle inner tubes in sight (quick snap of the local kids in the street ) - I paint a thin but complete coat of the PVA onto the binding channel - including the bottom edge (important) - then I do the same with the binding (again including the bottom edge) - I let it dry (15-20mins but once dry this will work even days later). You can tell it's dry because it goes clear. - and then I iron it on. I use an old heatshrink iron myself simply because MrsAndyjr1515 goes apes**t if I use her iron - but any hot iron (used dry) will do. - note no fibreglass reinforced tape. No bicycle inner tubes. AND THIS IS COMPETELY NON-TIME DEPENDANT so even here - halfway through, I can go for a coffee and comeback and carry on!!!! Basically, I position the binding in the slot and run the iron back and forward over the flat side of the binding, say, a couple of inches at a time. After 30 secs or so, I then hold the binding firm against the flat side and pressing it down to properly bottom to the channel floor (hence the gloves!) for 10 secs or so until the glue has sufficiently cooled to re-solidify the glue. - Note also IT IS COMPLETELY REPEATABLE. If after it's cooled, you realise say that there's a bit of a gap, you just iron it again until the glue melts and press it firm until it cools - once it has cooled, then it won't move again unless you re-iron it. So you don't need tape. The 6" attached above is the finished job! - once the whole length is attached, you can immediately start scraping / sanding / chiselling. There is no further glue setting time. - which is what I did. The binding on the right is where I was 1/2hr after the above photo: - and, ignoring the rookie tearout on the back wood mentioned in an earlier post, here's what the other side of the joint came out like: This method suits me personally much. much more than the first method. Just got to remember if there is ever a next time to do it this way next time!3 points

-

Warning! - this thread appears to have turned into full frontal Precision Porn. If you have been affected by images viewed (GAS), please seek help now, it's never too late.3 points

-

My beautiful 1990 Ken Smith BT4. It’s in excellent condition throughout, with some very minor crackling in the finish (so minor it’s hard to make out in the pictures). The previous owner (it was purchased on here) has fitted a new volume pot (purchased from Ken Smith), and a local luthier has checked out the input jack as it was a little intermittent - all now fixed, and I can provide paperwork of what was done. It comes with the original Ken Smith ‘teardrop’ case in 4/10 condition, and a really good TGI gig bag. The original Ken Smith leather strap is in there too. I’m really not looking for trades, but would be interested in some good quality guitars. Surprise me 😊 I’m in east London, and I think this one has to be collected, due to the two case thing. I’m ampless, so it’d be an acoustic try-out, unfortunately. You’re welcome to bring an amp, of course. Adam2 points

-

Spector Rebop 4MM (Blue Flame Maple) 5 months old (bought from Andertons) – completely unmarked and as new with tags New model with fully active EMG MM4 Pickup, Zinc/Bass Bridge and Spector Tone Pump Circuit. Complete with all tags, box and allen keys The playability of this bass is amazing in fact I am only selling to thin the herd. Sounds like a smoother stingray with tons of boost (treble or bass) on offer. I am only selling as I am wanting to thin the herd. No Trades please. Happy for collection. U.K. postage £20. Payment by BT, Paypal Gift or Cash. Anything else or questions, inbox me and I’ll give you my Mobile No. Check out feedback for Rhysyjob, cheers.2 points

-

TLDR Hello. Self taught, and been playing for 40+ years man and boy... started with punk in 76. then gave it all up 25 years later as pennyless and didn't want to die like Jaco. Back to it now after a 10 year hiatus of sorts, a slower, older more considered funky shredder. Still have the LesPaul but sold all the rest of me epic gear to pay for rent over the years 😞 currently learning a set for a band called Feast on Mars on the South coast PS. If any one sees my old Vigier Passion serial 0002 PM me instantly.2 points

-

2 points

-

Thanks guys. My post was a bit tongue in cheek as I have noticed my fingers going where I want them to on the fret board. I do play in our church band but am on a rota and only step up once a month with about 30 minutes of rehearsal before the morning service. It certainly focuses the mind!2 points

-

2 points

-

2 points

-

2 points

-

I don't think I've ever seen the expression "Enjoy Huddersfield" before.2 points

-

Thanks all for the input. I'm going to use the MOP. I spent most of today routing out the channels for the blocks. More or less I used @Christine's method, ie: 1. Masking tape on the back of the blocks, and the fretboard. Use centrelines to line them up. Thin superglue them in place. Score round the edge with a blade. Then VERY carefully prise them off. Very carefully. I had the corner of one break off because I went at it too quickly. 2. I found it useful to use masking tape to make clearer where the edge of the block is. Being a bit ditzy, I can very happily rout away, completely forgetting that I'm supposed to be stopping at the line. So the pink masking tape is there as a reminder! I then routed with my palm router (not a dremel) and a 3mm mill bit. I thought this stage was going to be the most difficult. Actually it wasn't. The router rode on two stacked pieces of 18mm mdf, either side of the neck and it went very smoothly. My palm router (a Dewalt, the best designed tool I own) has a light underneath so I was able to see pretty clearly. I hand routed to within 0.5 - 1mm or so. 3. Chisels to then cut up to the line. This was....less easy. Other than for prising templates off😲, I've never used a chisel in my life. I'm not even sure quite how to use them. Am I supposed to be hitting them with a malet? Just pushing then to sort of slice wood off? I used a combination of both techniques. I found that the most important thing was that they were sharp...(I'm a slow learner!).....I sharpened them before I started and half way through. Actually I think I should have sharpened them 3 or even 4 times. This was the end result... Not perfect, (and this is the best one) but I'm pretty happy. I'm hoping that epoxy and sanding dust will make up for my sloppy work....2 points

-

2 points

-

I too will purchase used instead of ordering new from EB. The new prices are far too much along with the wait time of 12 months for it to be delivered is pathetic. It should not take 12 months for a guitar that is machined to be made and sent to the UK from the US. If it was 1918 I could understand it but not in 2018.2 points

-

Ebay has got the exact same block inlay stickers that come from Japan for £7.69 with free p&p instead of £12.20 off Amazon 😀2 points

-

2 points

-

You don't want to hear what I'd play to that... Wold make Brotzmann or Zorn's Japanese Noisecore sound like a lullaby!2 points

-

I think the key here is that when the keys and electric overplayed on their own it sounded great and improved a bit of a bland song - when they all did it it was awful. In church bands there is a problem of musicians wanting to show off and not having learned the ability to listen and leave space for others2 points

-

2 points

-

Speak for yourself! I think it's not putting in the practice and study which is the issue. How many of us have the time to spend 8 hours a day practicing? Or even the willingness to? As one esteemed Basschater said to 'you don't need to learn how to slap to play Brown Sugar'. One of Steve Lawson's teachings is 'there are no secrets, here's how it's done'.2 points

-

My grandson, aged not quite 4 in this pic. And don't suggest getting him a ukulele, I already have. This is what he wants. I might try getting him an Ibanez Mikro. But when I give him the choice of any of my guitars / basses, he always says "I want the big one!" 🙂 But a good U-bass can sound surprisingly good for its size. I know a bass player who is having increasing problems with lifting weight and has gone from a P to a viola-bass to a U-bass. The U-bass sounds better than the viola imho.2 points

-

Is Australia ten years behind the world when it comes to fuzz?2 points

-

Just a quick note for anyone thinking about attending any of the Bass Bashes listed in this section - go! The Bass Bashes are informal get togethers of all things bass with people of all abilities with all types of gear. Don't be put off going if you think that they will be dominated by exceptionally talented folk continually slapping on boutique basses as that isn't the case (there will be boutique basses and a bit of slapping but there is more to the bashes). Folk turn up will all sorts of gear and its a great opportunity to try different kit and put faces to the names seen on here. I've met some great folks of all abilities at these and picked up lots of useful info. I've tried lots of basses I wouldn't normally get the opportunity to try and discovered I dislike some I've previously drooled over and really liked others I've dismissed!! For info, I don't play in a band, I'm not a particularly good bassist, I can't read music, I can't slap but I have a pretty decent amp and I make my own basses. If you're thinking about it, try to come along to one if you can. It's great that someone organises these and attendance will reward their efforts and ensure these events keep going. Hope to see you there! And there's usually cake too.....1 point

-

Made in Taiwan, I believe in 1998. Alder body, four string. Three band active EQ with full passive bypass. The pickup selector switch has been professionally changed. Dunlop Straplocks fitted - the bloody screw broke off when I was putting the straplock on the top horn so this one has been moved over slightly. Some minor dings on the body, tiny bit of buckle rash on the back and some scratching around the bottom of the body - all pictured. A couple of tiny dinks on the back of the neck, near the nut, which I've tried to photograph but are really not very significant. Nice low buzz free action, 2mm at the twelfth fret, a little bit of fret wear shown but nothing significant. Could do with new strings. Slight crackle on bass control which disappears if you give it a couple of twists. Weight 8.6 lbs on bathroom scales. Comes with a free 'Aum' sticker for added serenity. This doesn't cover any nastiness and can be removed if preferred. Prefer pickup from Milton Keynes but can ship at buyers risk/cost. £250 £225 cash or Bank Transfer. This is a really fruity and resonant bass with no real issues. Truss rod works fine and the EQ is incredibly versatile. I'm reluctant to sell but my addictive personality has resulted in a collection that's way too big so some of my less collectible stuff has got to go. having said that, it's a lot of bass for the money so please don't offend me with silly offers. Only trades I'd consider would concern Canon full frame camera gear. If anyone wants any more pics, let me know. Thanks for looking and have a fab weekend!1 point

-

This is very low. My low action goes from 1,5 mm under the C string (on my 6 strings basses) to 2 mm under the B string at 12th fret. That said on a P-Bass, a higher action means better dynamics. I set my newly acquired Fender Precision Bass AVRI '57 at 2 mm under the G string to 3 mm under the E string at 12th fret. This is just terrific sounding with new Ernie Ball flatwounds cobalt. Thanks @HazBeen for the tip for these strings. The pickup is also far away from the strings which gives also better dynamics. I'm now in the process of raising the action on all my basses as that very P-Bass effect is something I really like.1 point

-

1 point

-

1 point

-

1 point

-

No, never, any type of stropping causes rounding even if only microscopic which seems to make sharpening more difficult next time. The edge off a 6000 grit waterstone is as sharp as you'll ever need. The idea of pulling the blade backwards is for two reasons, the most important being that you polish the burr off rather than break it off and also so you don't dig into the stone damaging it as well as your blade1 point

-

1 point

-

Good technique can make not nice strings sound ok, but good technique and nice strings means you don't have to be thinking about your strings. This gives you headspace to count the correct amount of bars rest or try and decipher what the conductor actually wants.1 point

-

1 point

-

1 point

-

McCartney does use a double. I had a tutor at uni who was working with McCartney in a studio somewhere. She was shocked when she walked out of the room to go to the loo, leaving McCartney behind her, only to bump into him coming out of the gents. Apparently it’s for security since Lennon was shot. The real one goes out the back door, the double out through the front door.1 point

-

1 point

-

Btw sound clips planned for this weekend!1 point

-

http://thunderbuckerranch.com/ the 66 series1 point

-

1 point

-

I grew up listening to the Stax, Atlantic, American and Fame studio guys. There's not an ounce of fat on any of those songs from any musician.1 point

-

One big one is volume Second big one should clunk or click in the middle...that’s a pickup pan. Towards the bridge is for bridge pickup, towards neck the P pickup. nearest the neck (I think) is bass, middle is mid frequency, and bridge end is treble/high frequency.1 point

-

1 point

-

I recommend it, and I've been a individual-pedals-on-a-board guy since forever. The Z-Tron envelope filter, B7K and Sansamp models are my favourites, I could easily gig with just this. Although I expect to move to a Line6 Helix HX once they add the Sansamp model they've been hinting at! Much easier to use and better sounding (in terms of amp sims and dirt at least) than the B3 / B1on.1 point

-

You could buy 5-10 vintage v4 reissues for the price of a USA precision. I love my v4s to bits. BUT from what I can see, despite being called v4, the models are all slightly different. The blk standard is my main bass. Love it. Laqured neck. Very easy to play, loads of tone control and power. The v4 icon has an un laquered neck and different sounding pick ups. Definitely more vintage sounding. One thing I have done is put shielding tape all over the back of the scratchplate and cavities. Works a treat. Cost less than a tender for a huge roll. The blk was bought new for £230 (and I swapped for identical Wilkinson gold hardware). The icon was bought as new for £95. One weird thing I will mention is I have absolutely no idea how the pots are wired! I'm issued to one being volume, and one tone. These definitely are not that simple. The tone control definitely adds volume too the more you go to fully open. But it does add even more tone shaping possibilities. I've had an excellent USA p in the past, the finish was like a work of art. But I genuinely feel these v4s are more playable and have more character about them. And cost nearly 10 times less. If you had a range of them - with their different types of neck (laqured or unlaquered) and pick ups (modern or vintage), and you can buy straight replacement hardware in different colors, and scratchplates - you could create an awesome bitsa to your exact spec for next to nothing.1 point

-

Truth is, in the late 70s, the bass guitar was THE instrument to play in a band if you had any aspiration to be a 'good' player - there was quite a history of people wanting to be accepted dating back to the earliest days of 'progressive' (when everyone from Floyd to Fleetwood Mac to Blodwyn Pig were included in that 'genre') to the early 70s Yes and the like wanting acceptance as a 'serious' musician - unless you were a kid playing punk (and there weren't that many of them in spite of what one part of the music press would have you believe) you would be a serious rock or R and B player at that time (R and B including disco and jazz funk, Rock including prog). The most dynamic and exciting form of bass playing (for players and audiences) was slap bass. I heard players like Pops Popwell with the Crusaders long before I knew about Larry Graham's earlier stuff - GCS was an upcoming band in the UK on a par with Kokomo - they were not stars. Any bass player with any aspiration to play R and B or pop would be playing slap - in fact if you turned up at an audition and couldn't, for such a band you would likely not get the job - by the early 80s it was essential. Pino was even doing it on a Fretless at that time!! So I see no reason why MK wouldn't have been influenced by much of what was going on around him - that he was clearly looking for a Stanley Clarke sound and earlyish songs like Heathrow had bass parts bearing great resemblance to SC's lines (Lopsy Lu for example). However the first single (Love Meeting Love), a finger style part, has, I think been attributed to him playing a borrowed EB2 during his shop days - and his interest in a JD was sparked by seeing/hearing Gary Barnacle's brother's white JD - no doubt because of its ability to sound and vaguely look Alembic at a fraction of the cost. Also, at this time, although people may have been influenced by the likes of Jamerson, Babbitt etc - well at least their more famous parts (and remember in the 60s you couldn't hear the bass properly anyway), people were more likely to be influenced by this new wave of players like Bernard Edwards, Stanley Clarke, Pino Palladino and the disco players like Louis Johnson - and really any prominent bass part (Fatback Band, Ain't No Stopping Us Now, Earth Wind and Fire). Unfortunately we suffer from a gradual re-write of history - fuelled by BBC documentaries (which fail to mention such seminal programmes as The Tube by Channel 4 and overly rely on the NME as a source, when it wasn't generally representative), music school resources (Scotts Bass Lessons Included) seemingly focus on the excellent but at the time barely audible and certainly in the 70s, far less relevant early Motown stuff. The 70s/80s was a far more exciting time as a bass player in my view. I am personally doubtful MK would have failed to be influenced by everything music wise and bass wise going on around him - and particularly working in a shop - that he only focusses on snippets and major stuff in interviews is hardly surprising.1 point

-

I went to see Einstürzende Neubauten at a free frestival in Ypres, Belgium on Saturday. It was part of a series of events that are commemorating the end of World War One. I then saw them again in Heerlen, Netherlands, last night. Have a restful day today, then a long drive back to Wales tomorrow..1 point

-

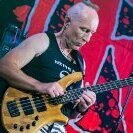

Actual photo of me, minus the bass but you’ll have to take my word on that:1 point