-

Posts

2,539 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Shop

Articles

Everything posted by JPJ

-

Just a couple of camera phone shots for tonight She's actually much darker in the flesh And the troublesome edge! Didn't get to do any work on her tonight so I'll hopefully start cutting back tomorrow night Enjoy!

-

[quote name='JMT3781' post='891913' date='Jul 11 2010, 12:32 PM']I've putting this off far too long.. One of those where i always sit down to play it and just give up after 10 mins cuz i cant keep my mind on it.. Todays the day Anyone else want to take the teen town sunday challenge? Could get interesting.. Could have a different song every sunday that we take turns to pick.. variety of difficulties Maybe call it "The Basschat self improvement and support society" Any Takers lol?[/quote] Self-improvement Sunday, that has a certain ring to it

-

[quote name='EBS_freak' post='619028' date='Oct 6 2009, 09:12 PM']Hi JPJ - did you ever get to finish this or did the top still give you grief?![/quote] Well, after leaving this at the back of the cupboard for a while, I've restarted work on it. I had trouble with both the top and the join line between the maple and the swamp ash which was really caused by me being a bit of a numpt and trying to take the solid black over the radius of the maple. Having tried that unsuccesfully a couple of times, I've now gone with having the joint between the stain and the solid colour on the join line of the maple and swamp ash and I'm really pleased with the result. The top isnt perfect, but then again, I was probably trying for a level of perfection higher than the piece of maple would allow. It seemed like everytime I sanded one set of defects out, another set would appear, to the point where what started as a 6mm cap is now down to about 4.5mm! Yesterday I sprayed the top with lacquer to seal it so that I could wet sand the back and sides this week and even though this is just the first of many coats of lacquer, the result is really pleasing. I may even post a picture or two later So the project is back on again, and its my intention to finish the body this week so that the lacquer can have a good four weeks to harden before I assemble her whilst on holiday in August. I'm so pleased with the finish so far, I might just build another project bass...........

-

-

Would you fit a J Retro preamp into a vintage jazz bass?

JPJ replied to Gunsfreddy2003's topic in Accessories and Misc

I have two j-retro equipped5 string jazz basses, my Overwater came equipped with one and I already had one in my Fender DLX. I also have a homebuilt precision v with John's BTB and mid-stack. I can't speak highly enough of John's work. His circuits are first rate and give that classic fender bass tone, that somehow sits so well in a band mix. I have no problem recommending him to you. -

-

-

-

-

-

Spector TonePump Active Circuit

JPJ replied to JPJ's topic in Accessories & Other Musically Related Items For Sale

-

[quote name='silverfoxnik' post='876018' date='Jun 23 2010, 11:42 PM']I had one of these for 2 years; same colour, though mine had an EBS pre in it.. Really nice bass! Good luck with the sale..[/quote] Cheers, They are really nice basses, and since advertising it on here I've been playing it again, maybe I should ignore the GAS god's and keep her?

-

[quote name='Marcus' post='875715' date='Jun 23 2010, 06:46 PM']That "The Office" by any chance ? Dirty South...... gan on !![/quote] Houghton Buffs actually

-

Here's a shot of my rig in its natural environment

-

Call me a luddite but big and heavy is the only thing that delivers the type of bass I like on stage. Without bashing on, my SWR SM1500 is too heavy for me to lift onto the top of my two Goliath 4x10's on my own. The Goliaths I can just about lift on my own (one at a time!) and they fail the Warwickhunt door test miserably (just look at my knuckles after a gig if you dont believe me). But that's the downside. The upside is a big phat bass tone where ever I wander (on stage and off since I've gone wireless) and compliments from band mates and sound men about how good my bass sounds and sits in the mix. I've tried small stuff (anybody remember the Carlsbro Delta stuff with the 8" speakers?) and for me it doesnt deliver.

-

-

-

-

-

-

-

-

Here we have my USA Fender Jazz five string which I’ve owned for about the last six/seven years. The bass is the 1996 Anniversary DLX model which I have upgraded with Hipshot Ultralite tuners, Schaller strap locks and a J-Retro active circuit. The bass is finished in a interesting red colour which has a darker band around the edge (like a sunburst) and has a mother of pearl type scratchplate. The neck is narrow for a five string (what attracted me in the first place) and is reasonably light weight and comfortable to play. The bass comes with a Bass Centre Hiscox moulded flight case. Again, the bass is well played though the battle scars on this one are limited to four ugly chips on the bottom edge of the bass (probably from an unprotected guitar stand). Pricewise, as is with the Hipshots and J-Retro, I’m looking for £600 (including the original Fender tuners and active circuit). In original config, I’m looking for £450. Delivery will be extra, but I will be prepared to meet up / deliver up to 100 miles from Newcastle upon Tyne free of charge. Any questions, please ask.

-

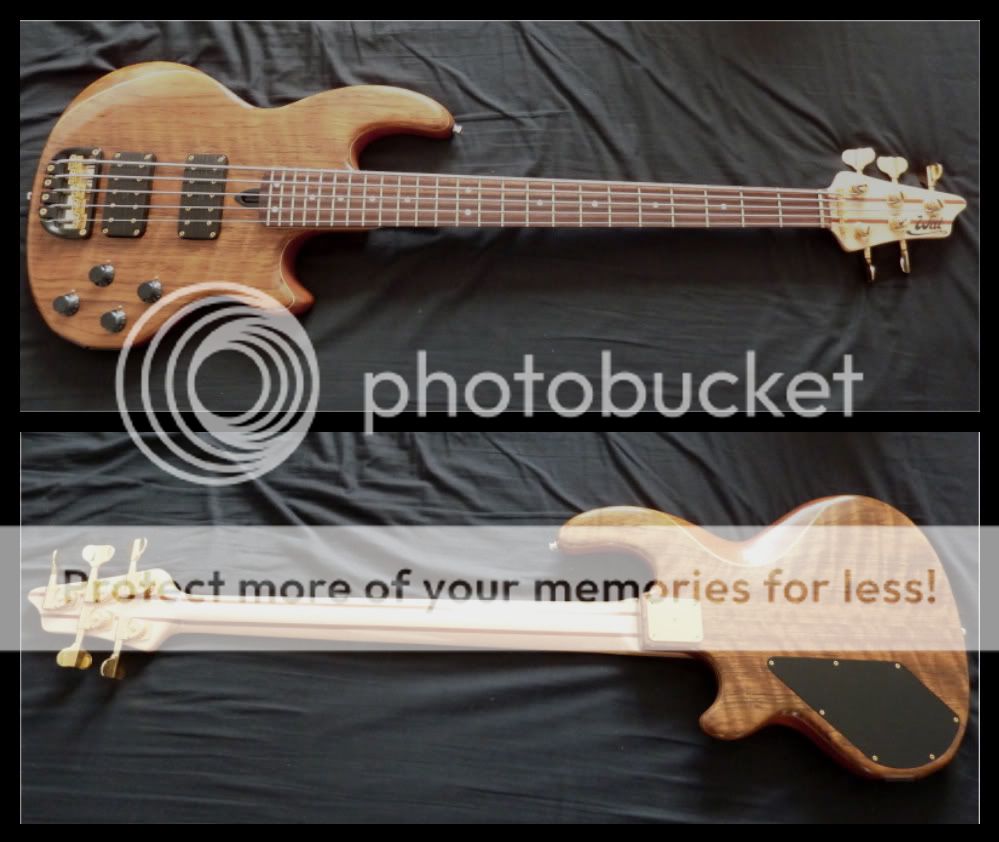

I recently bought this from respected Basschat member and Spector authority NickSpector. I have spent a bit of dosh and some elbow grease to return the bass to the factory original config of EMG Hz pickups with EMG two band active eq. I’ve also added Schaller strap locks and removed the stick on MOP fret markers. As you can see from the photographs, the bass is in trans black finish (See through quilted maple top, solid back and sides) and is the five string variant of the Rex Brown (Pantera / Down). Its from Spector’s Korean factory and is neck through construction. The bass is well played, and has a few cosmetic battle scars including a bit of pick rash on the front and some light scratches on the back. None of the scratches are through the finish and may polish out with t-cut or similar. The bass comes with the fitted Spector case (shown in the pictures). I’m looking for £450, delivery will be extra, but I will be prepared to meet up / deliver up to 100 miles from Newcastle upon Tyne free of charge. Not interested in trades (unless you have an Overwater J series five string). Any questions, please ask.

-