-

Posts

203 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Events

Shop

Articles

Posts posted by Basvarken

-

-

My latest build has a nice burst:

-

2

2

-

-

it is coming along nicely 😉

-

5

5

-

-

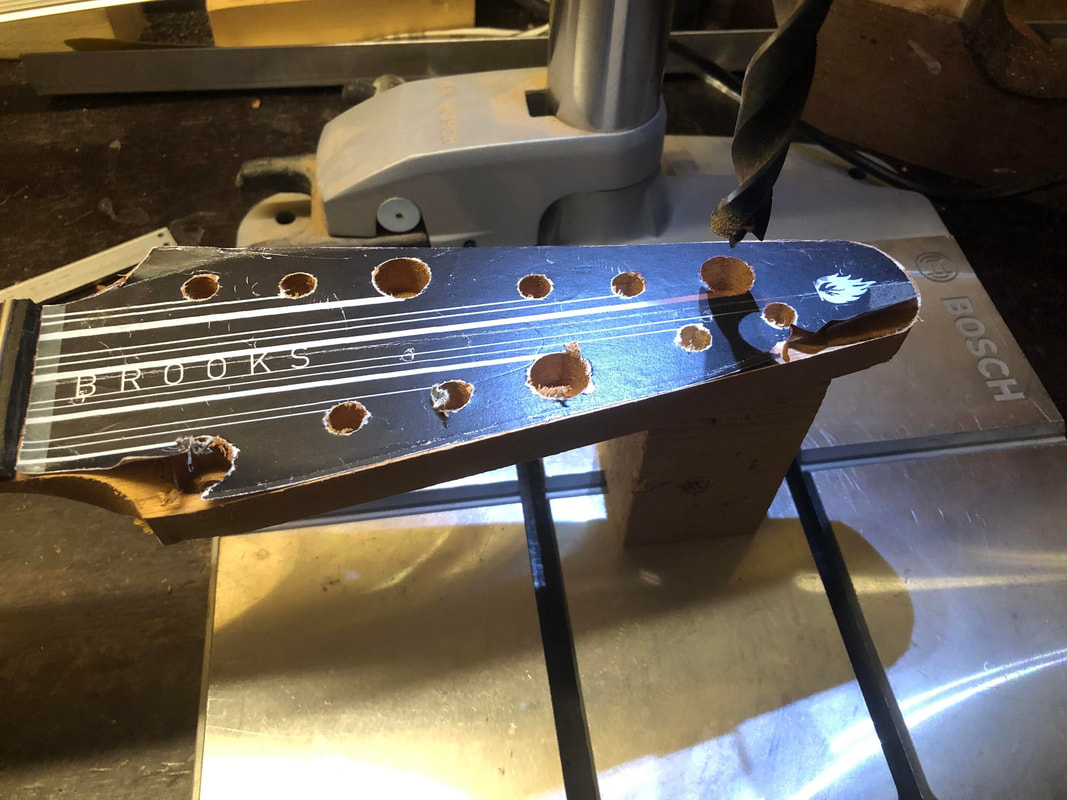

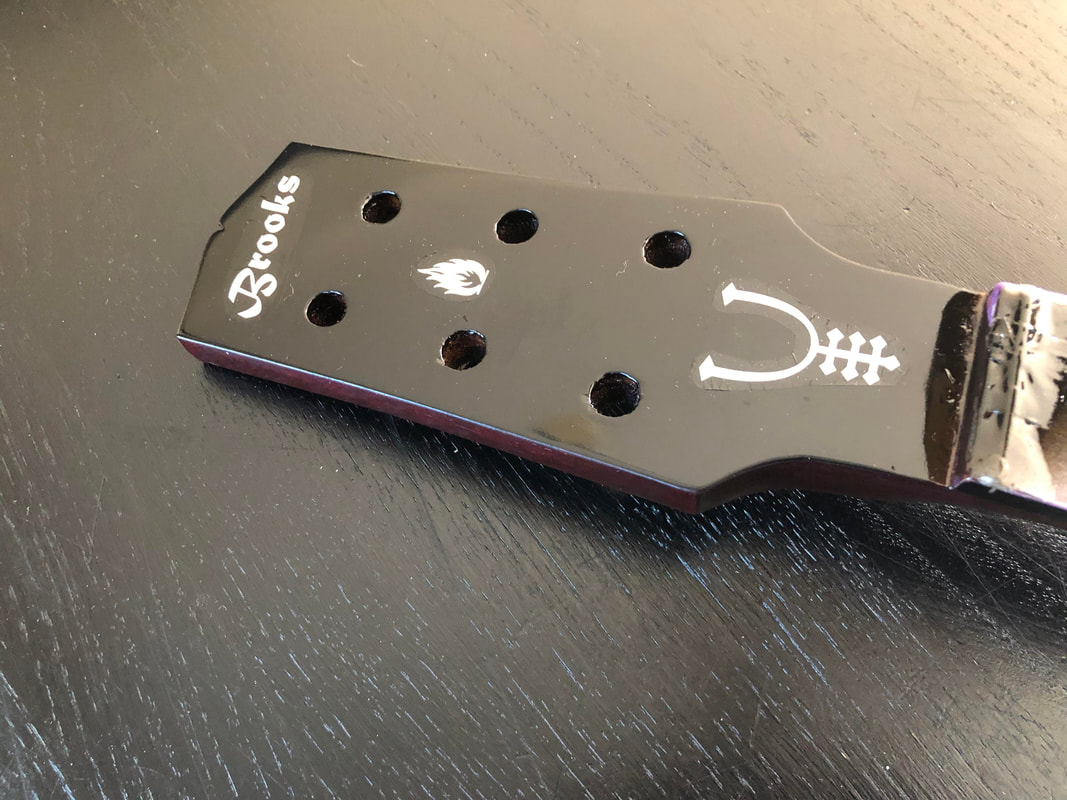

Headstock of the Brooks EXB-MS-10, a ten-string multi-scale bass.

Bass tuners are Gotoh GB350 (Res-o-lite). Octave tuners are Gotoh CXB-01 (carbon base plate).

-

3

3

-

-

18 hours ago, Richard R said:

That is quite astonishing. How long did the build take you, including the thinking and planning which must have been considerable?

From the initial idea and sketches to the completed build, I'd say about a year.

The actual build took about four months (in my spare time)

Then I had to wait about two months till the built in effects were ready.-

1

1

-

2

2

-

-

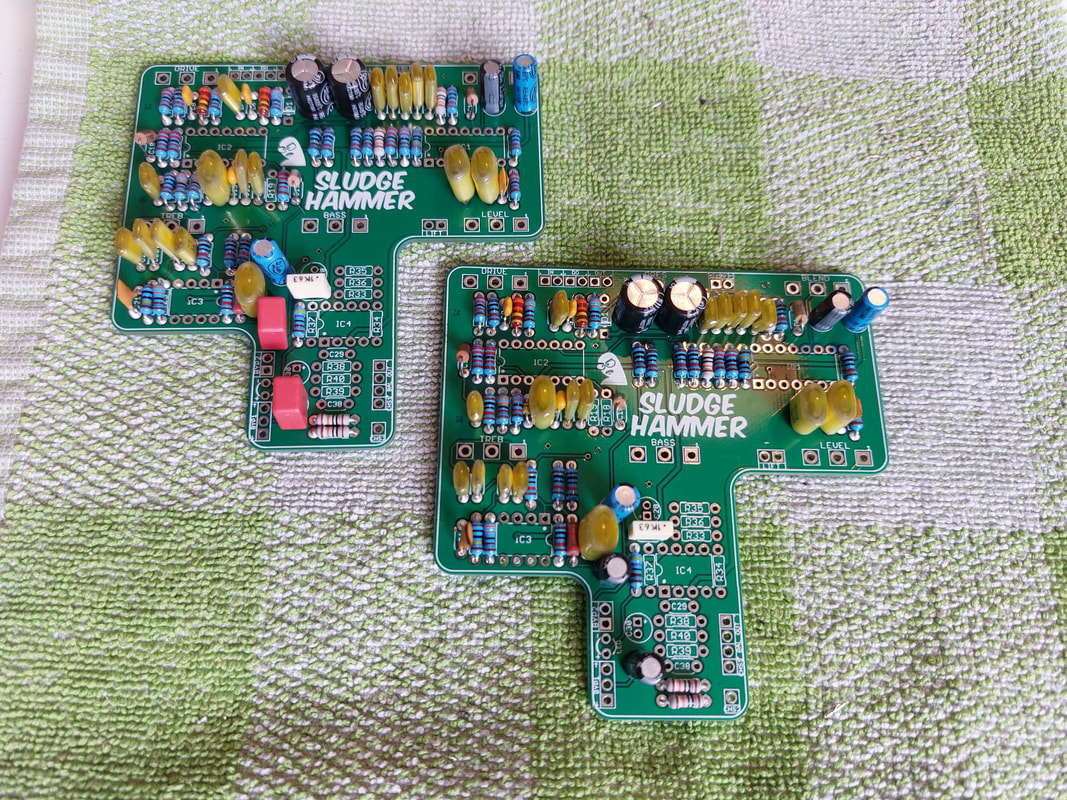

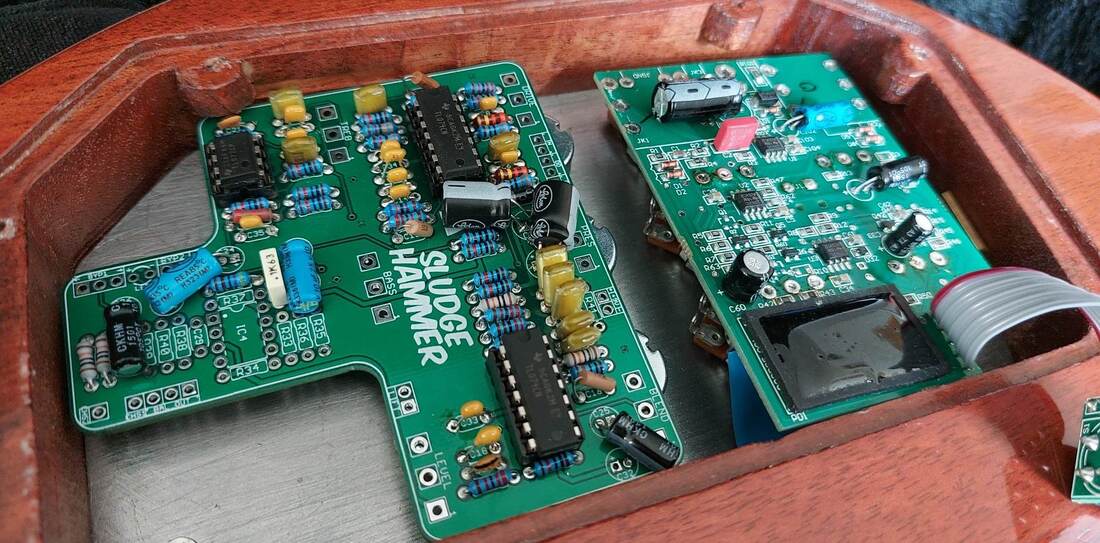

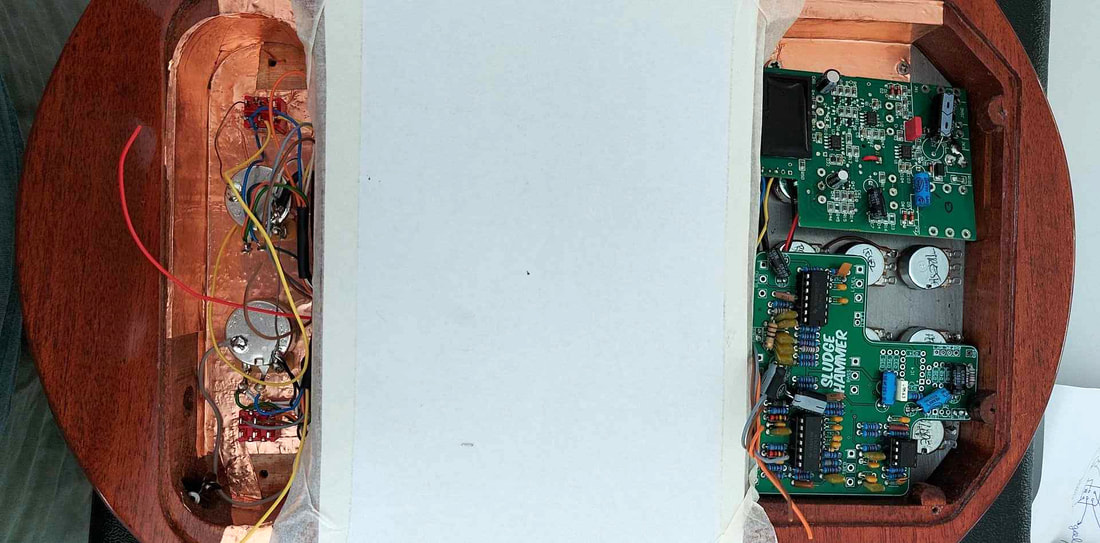

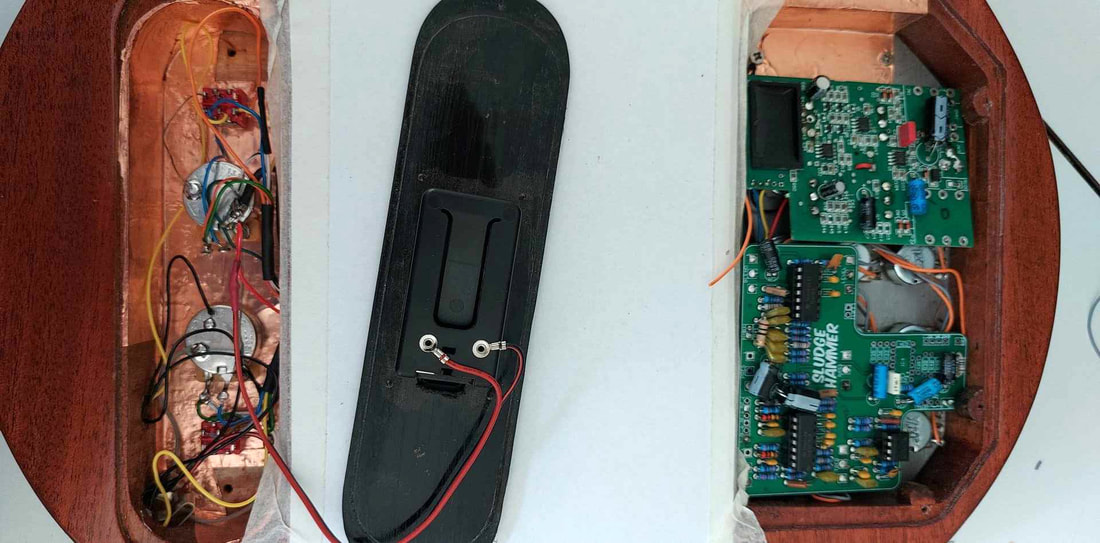

Enter Bas Becu of BQ Music

I had asked him to build a SansAmp type over drive for this bass.

Almost ready except for the led lights

-

12

12

-

-

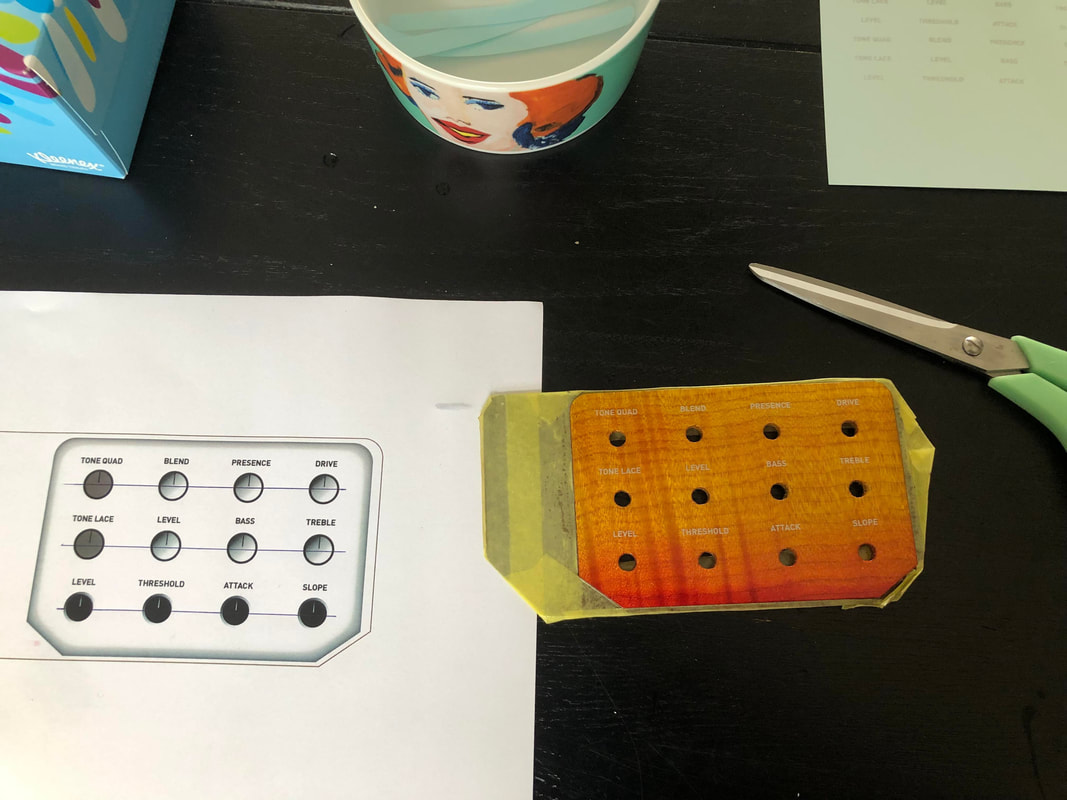

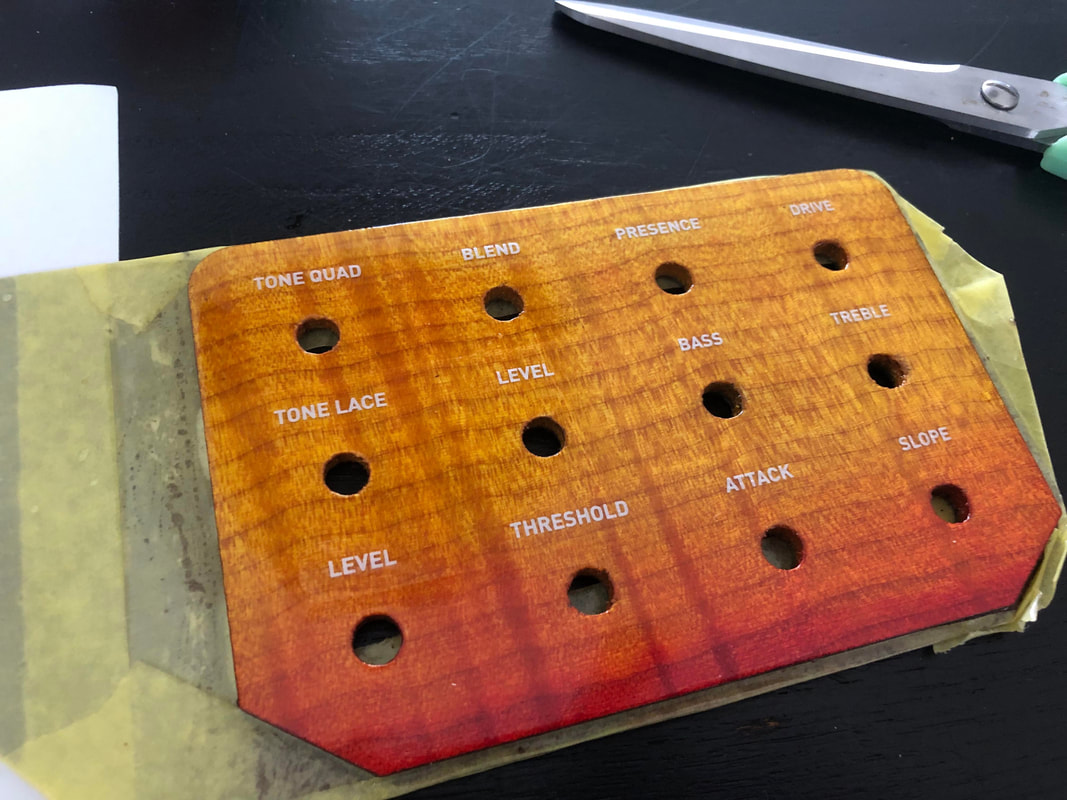

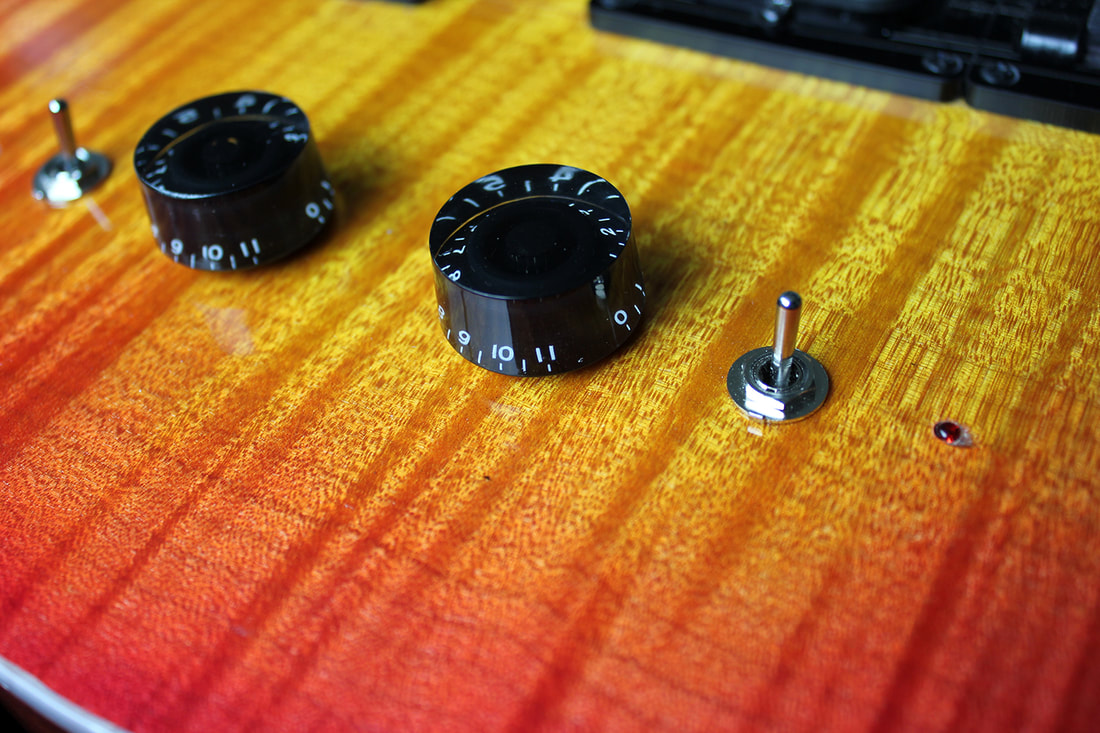

First applied the yellow all over.

The did the red on the outlines while the yellow was still wet.

And feathered them to the inside with a dry brush.

After the first few layers of lear it already looked gorgeous

and a few layers later...

The effects panel go the same treatment.

And when it had enough layers of lear to be perfectly flat, I applied the lettering for the effects with decals

When the lacquer process was done, and after the polishing I could start mounting the pickups.

Then put the tuners and bridge on. And strung her up for the first time.

-

6

6

-

-

I made some cover for the effects panel and control panel of left over pieces of Khaya.

But also made them out of plastic. Because I wasn't 100% sure about the wooden ones...

-

4

4

-

-

When the neck profile was done I drilled the holes for the tuners

And did the final shaping of the headstock

Routed the neck pocket

Shaped the heel to make it a perfect fit

Used a an aluminum profile as a straight egde to check the angle of the neck

Starting to look like a bass...

(Neck not glued in yet)

Drilled the output holes

And some more holes

-

5

5

-

-

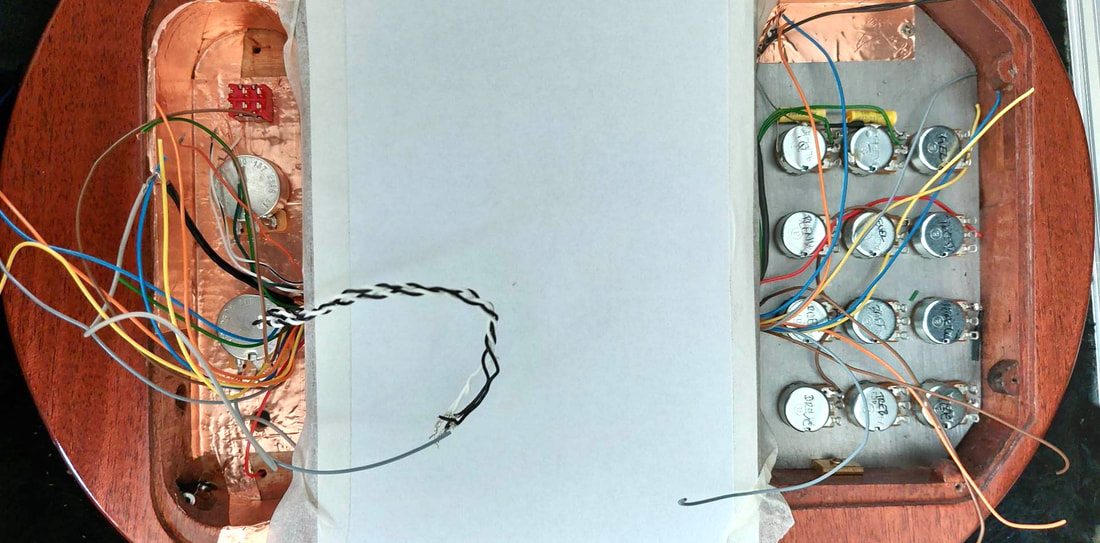

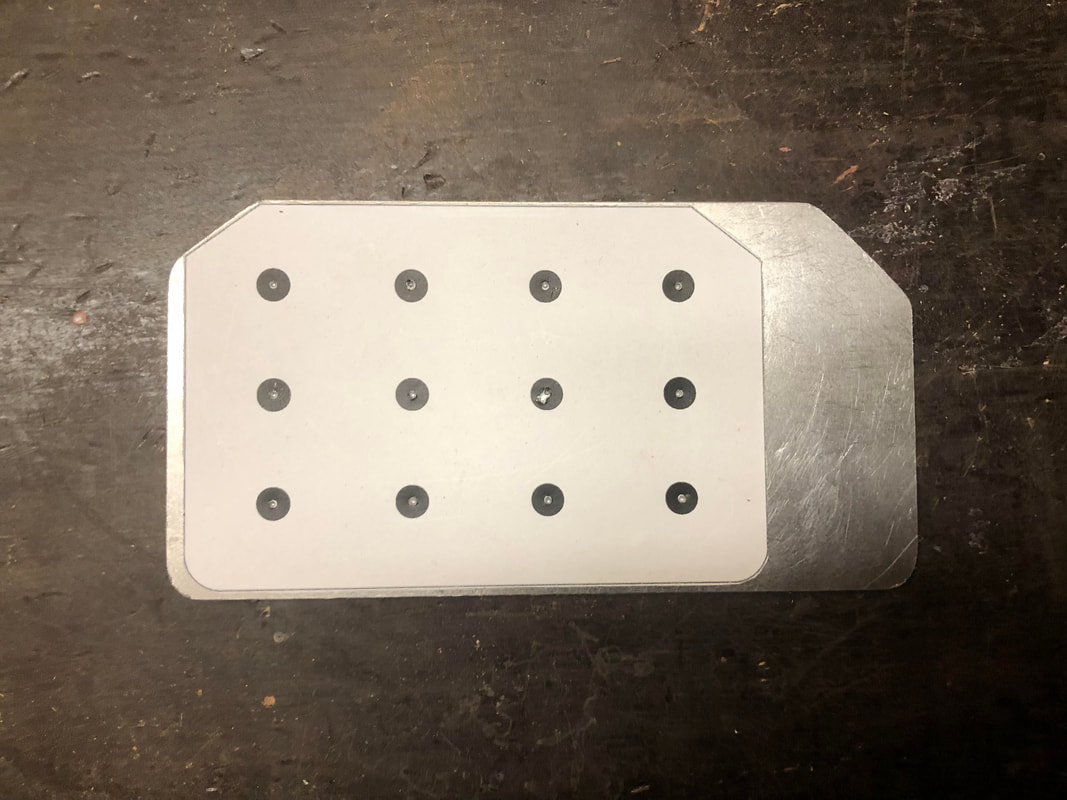

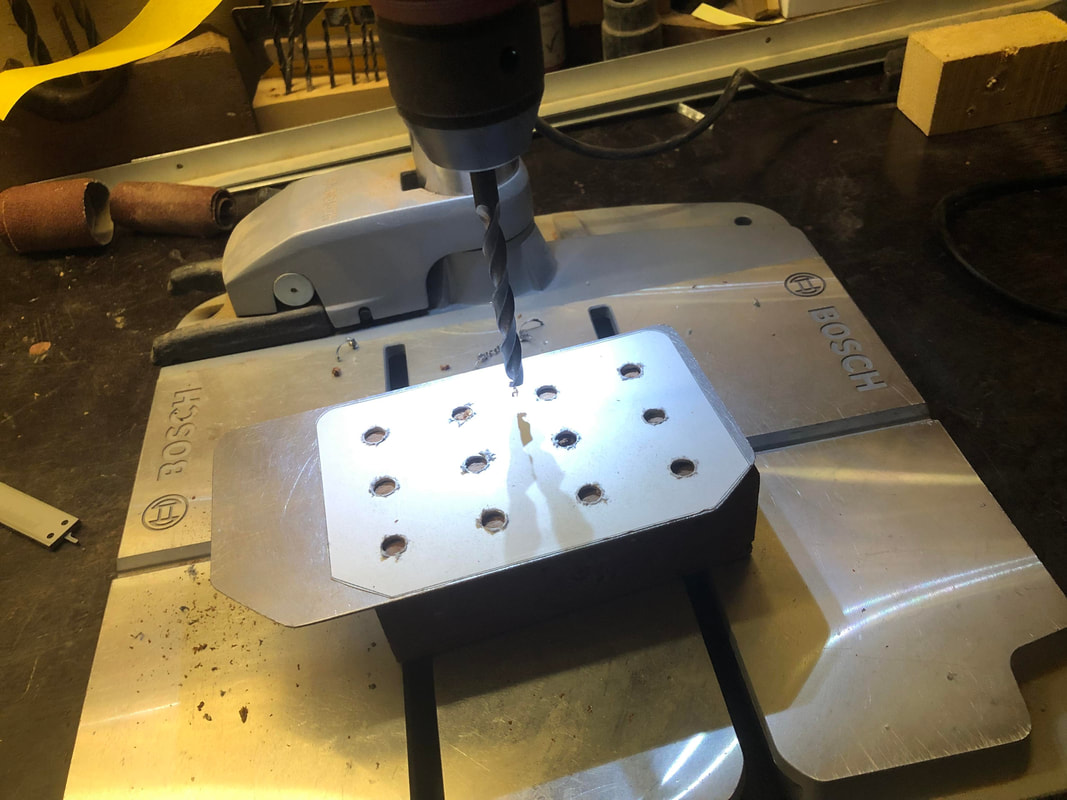

Then made the mounting plate for the effects panel. I chose a thin plate of steel.

To save weight and to make sure it would take up too much height in the effects panel (as it would get pretty crowded in there later on)

Made the holes for all the pots

The glued on the laser cut flamed maple panel. It had sanded it much thinner, in order to get the right height for the knobs. I didn't want them to protrude above the top of the body.

The drilled the holes for the potentiometers.

-

5

5

-

-

Back to the neck.

The fretboard was glued on and I left it alone for while.

Now I could start shaping the neck

And when the neck profile was almost ready I did the side dots

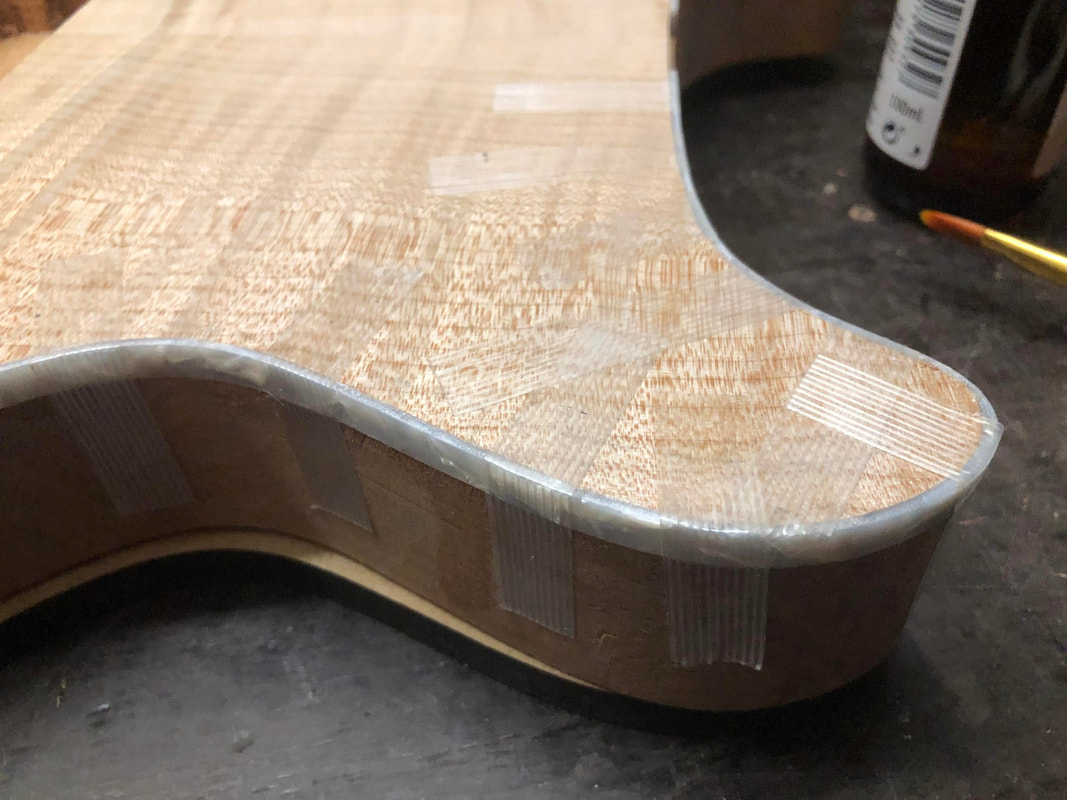

Routed the profile for the binding around the top of the body

Glued the pearloid binding in.

I use acetone because the bass will be stained. And stained does not work on spots where glue was spilled.

Acetone leaves no residue.

Attention shifted to the back side of the body:

Routing the profile for the controls cover.

And the wider cavity for the effects

So far so good

-

5

5

-

-

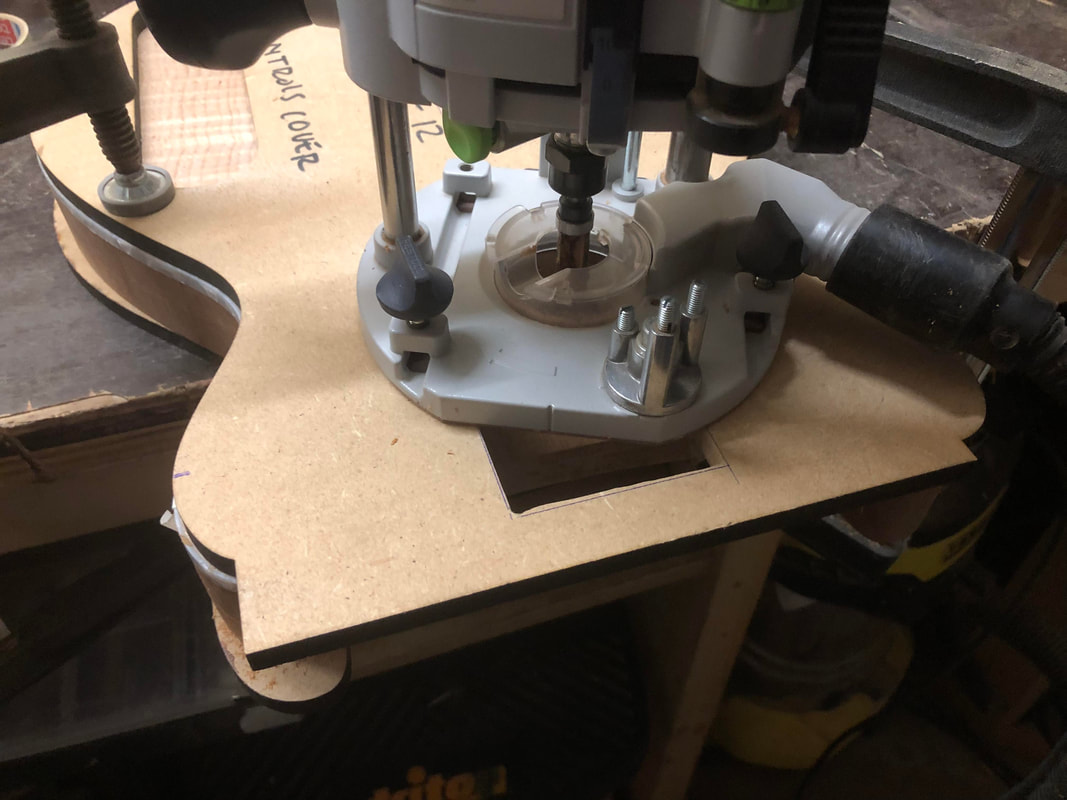

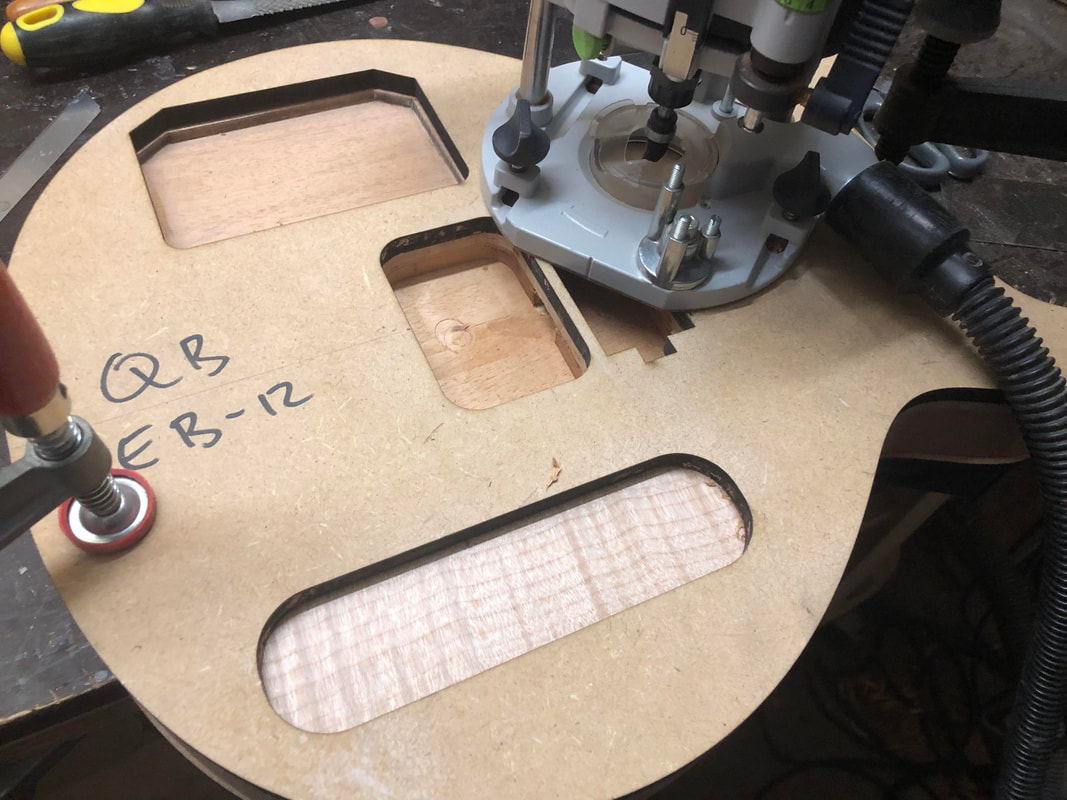

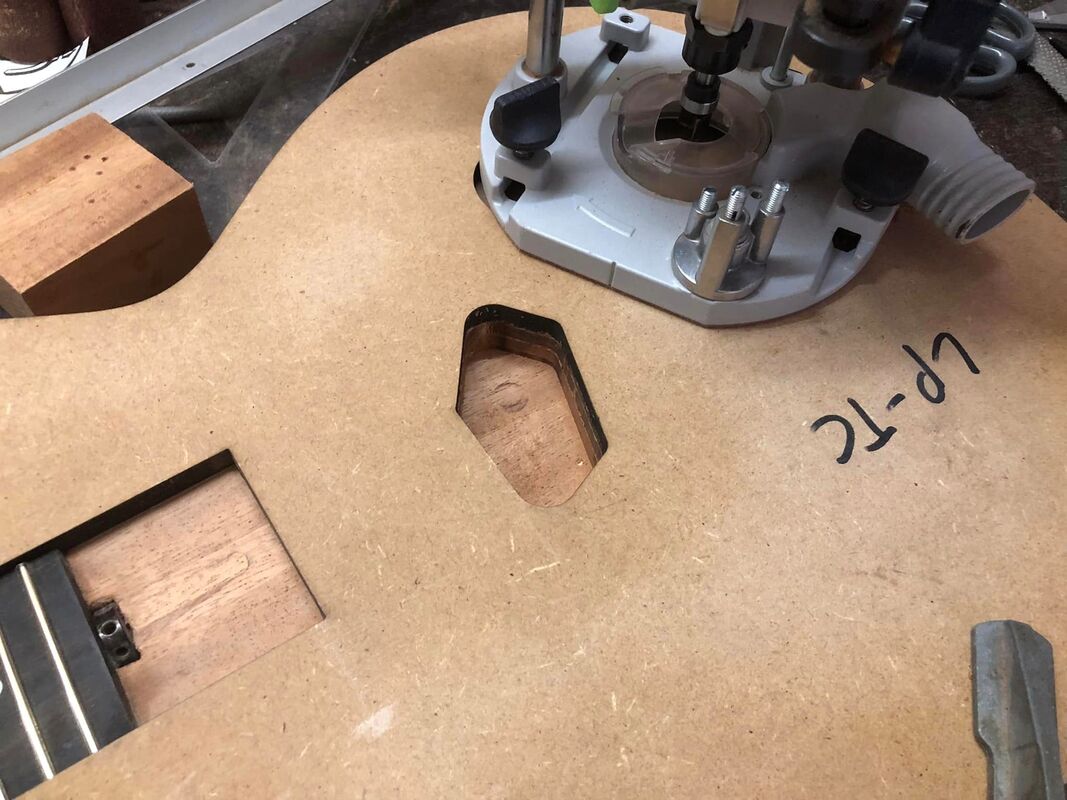

Then back to the body

Routing the channels for the wiring first

And glued in a piece of mahogany because that is where the channel later meets the effects cavity

Then routed the controls cavity

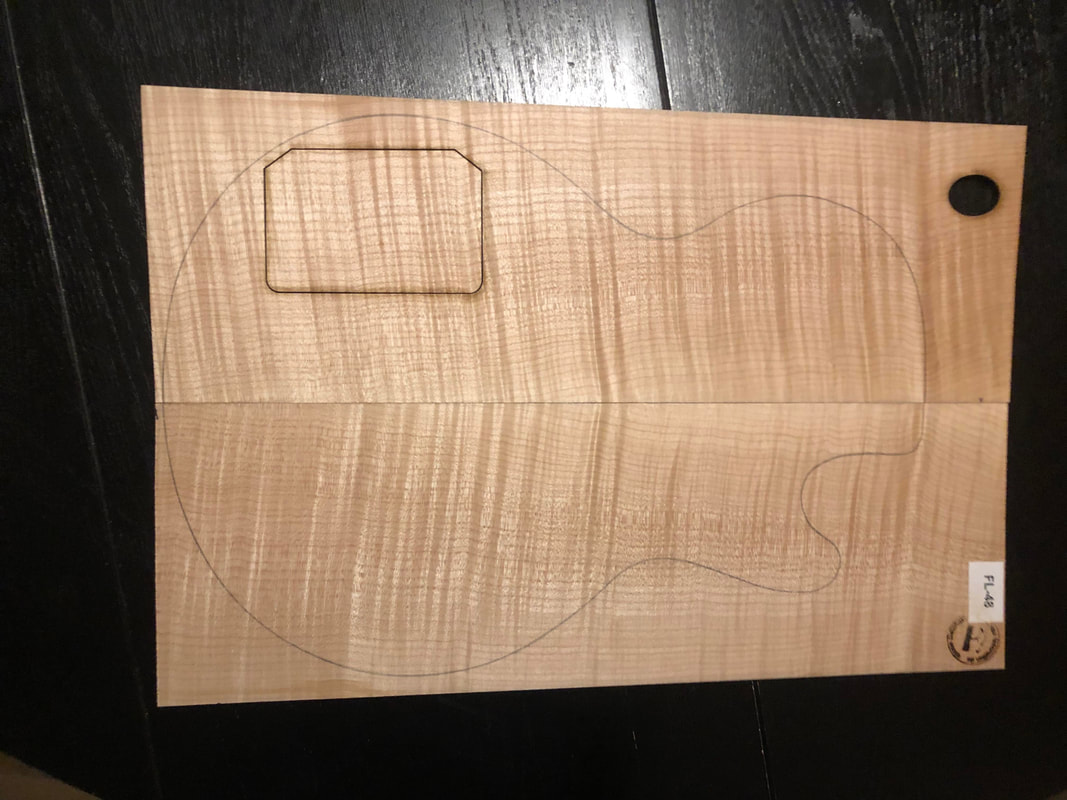

Roughly cut out the outline for the flamed maple top. And glued it onto the body.

And then routed along the template

Up next was routing the pickup cavities

And squaring the corners with a chisel

Routed the effects panel cavity

Test fitted the panel itself.

Of course it fits. It was laser cut. But I just had to do it 😉

-

4

4

-

-

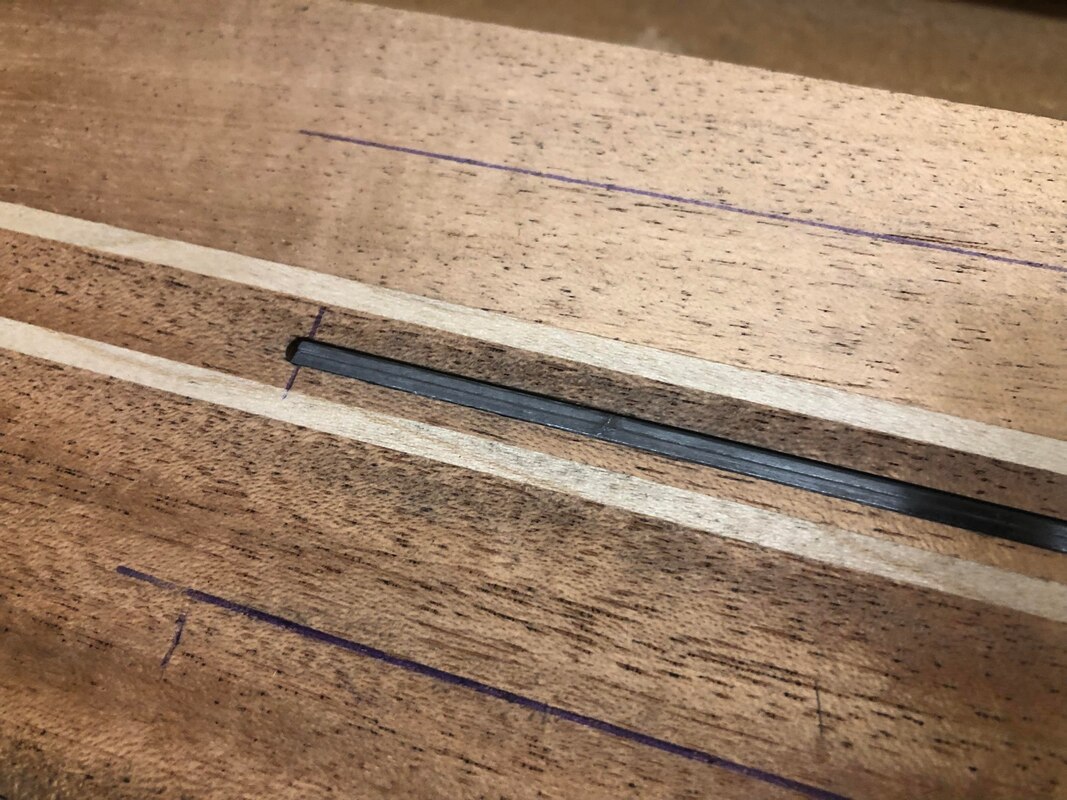

With all that sorted, I started working on the neck.

Routing for the stiffening rod first.

And then the two slots for the truss rods.

The controls panel in the bookmatched set was laser cut.

This way the grain would continue perfectly with the rest of the top

It took me a while to find the right knobs for this panel. Especially the size was rather difficult. Most knobs are too big. And they would be too close to each other as a result

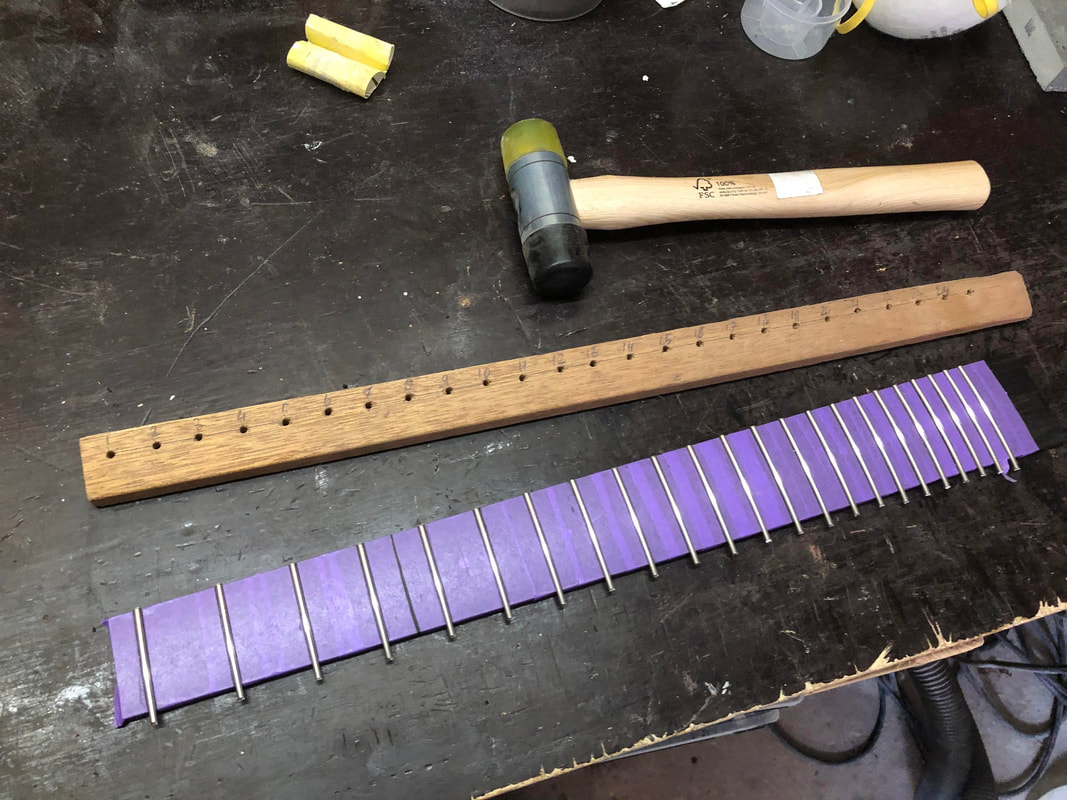

Up next was the fretboard. This one did not get inlays on top.

I cut out the truss rod access slot at the end of the fretboard

And make a cover for it from the same piece of ebony

In the meanwhile I had roughly shaped the neck. So that I could glue the fretboard on.

I always use strips of inner bicycle tubes as a clamp for very ven pressure all around.

-

5

5

-

-

Each build start with selecting the right wood.

My supplier made this body blank out of two pieces of Khaya Mahogany

And from the same batch of (lightweight) Khaya I selected a piece for the neck blank.

It was sawed in three pieces and laminated with pieces of Maple in between. Already pretty sturdy and stiff. Ideal for a bass neck that has to withstand a lot of tension

From master carpenter Frank Hoffmeyer (Holz Faszination) I scored a beautiful set of flamed maple and a very nice piece of ebony for the fretboard.

A while ago I bought a few bridge sets from a German company that makes hardware for Ritter and Marleaux.

This is the last one I had. Im not sure if I'll ever buy from them again. But that has nothing to do with the quality. Which is outstanding...

The neck features two spokewheel truss rods and one carbon stiffening rod

To make sure this bass does not suffer neck dive I used lightweight tuners by Gotoh.

Res-o-lite for the bas strings. And Stealth for the octave strings

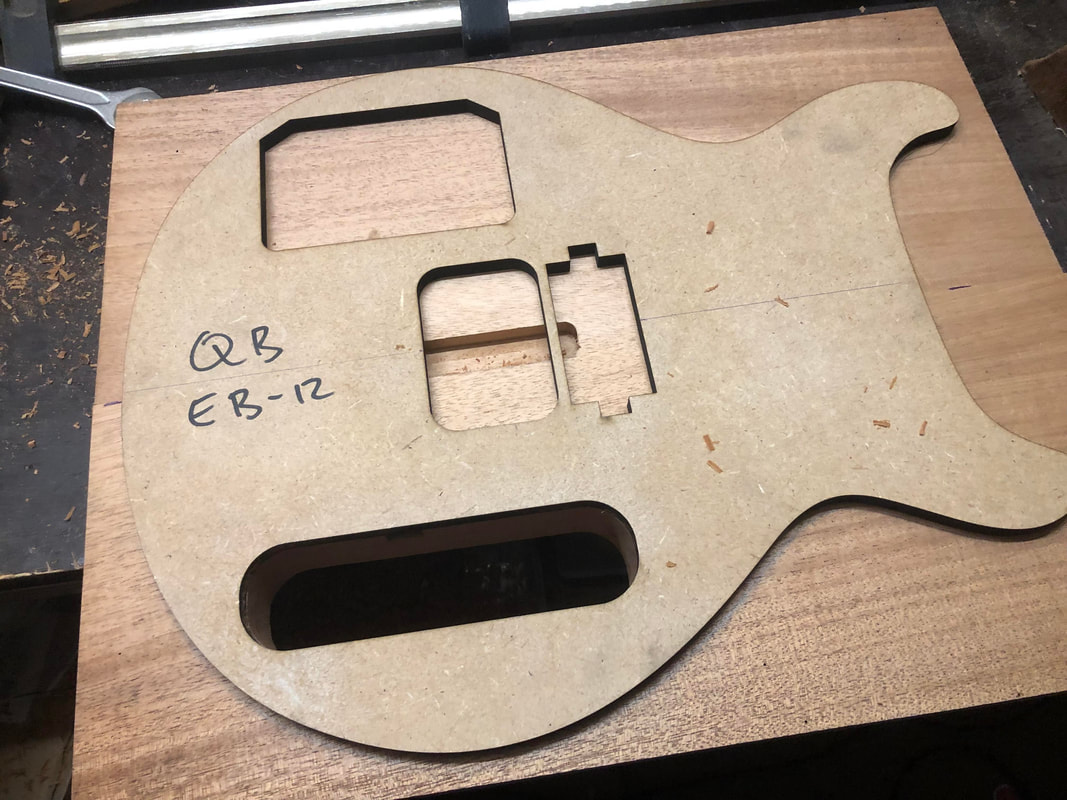

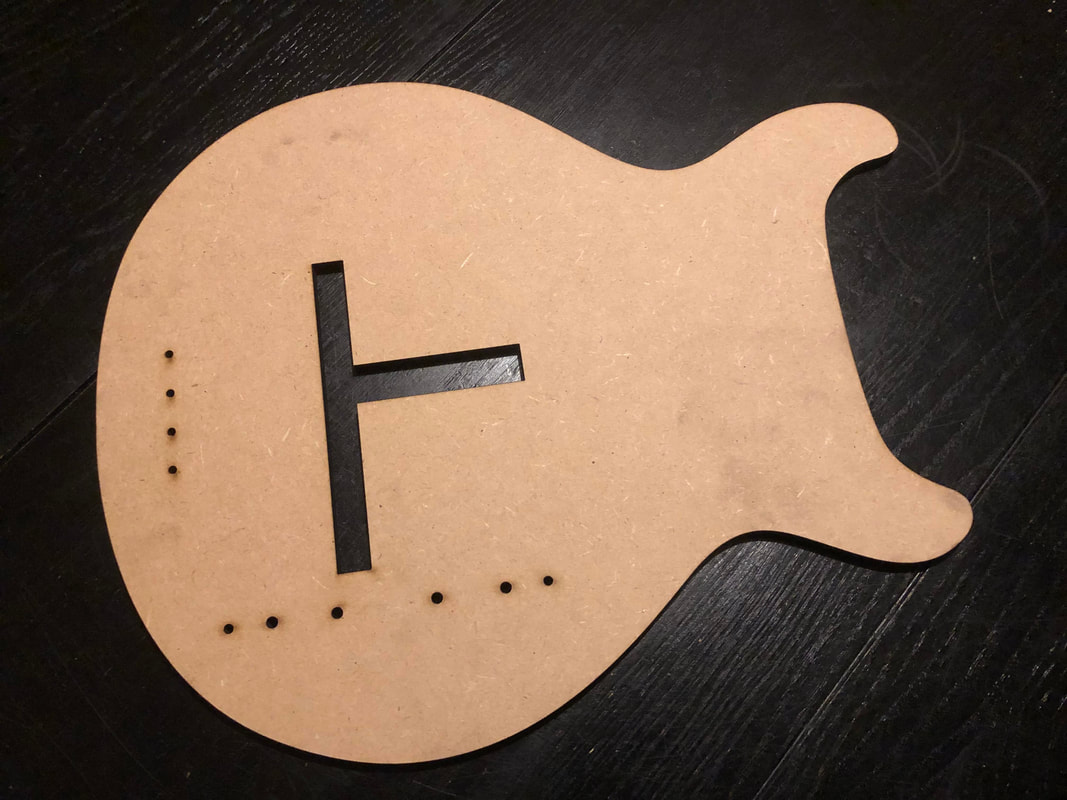

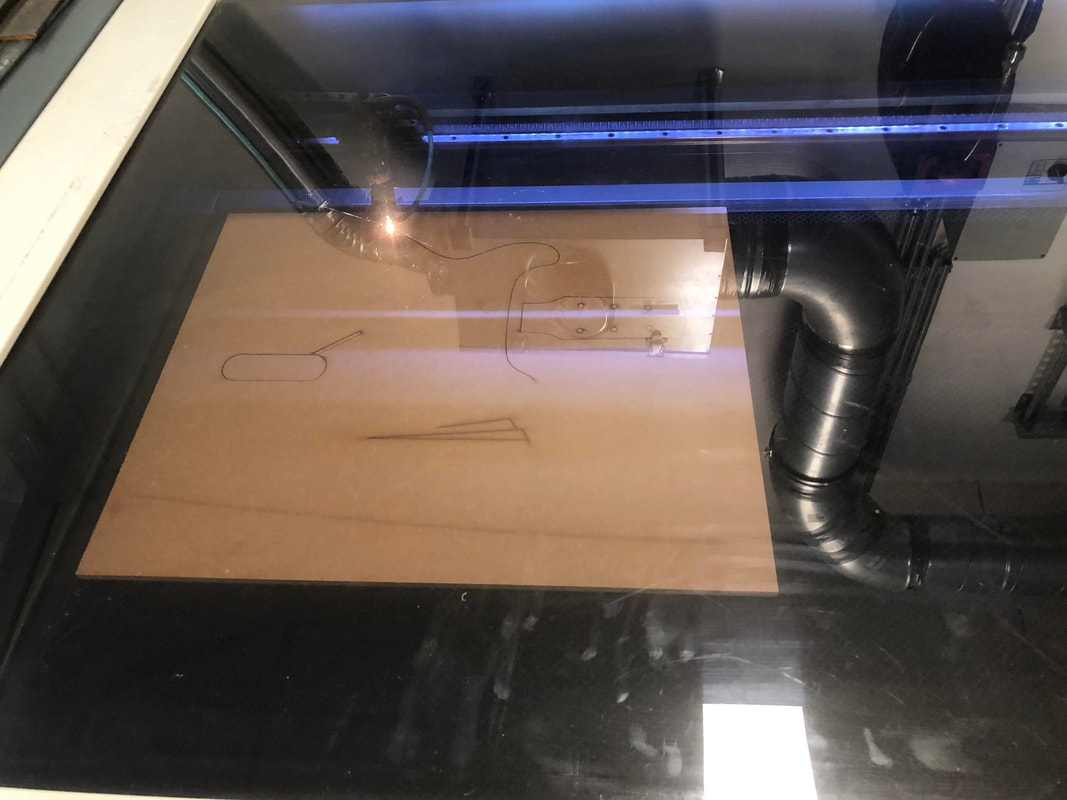

After the design was ready I made templates for the routing.

I laser cut these at a FabLab which is in-house at my employer.

Making these templates always requires some good thinking ahead. But it all worked out according to plan 😉

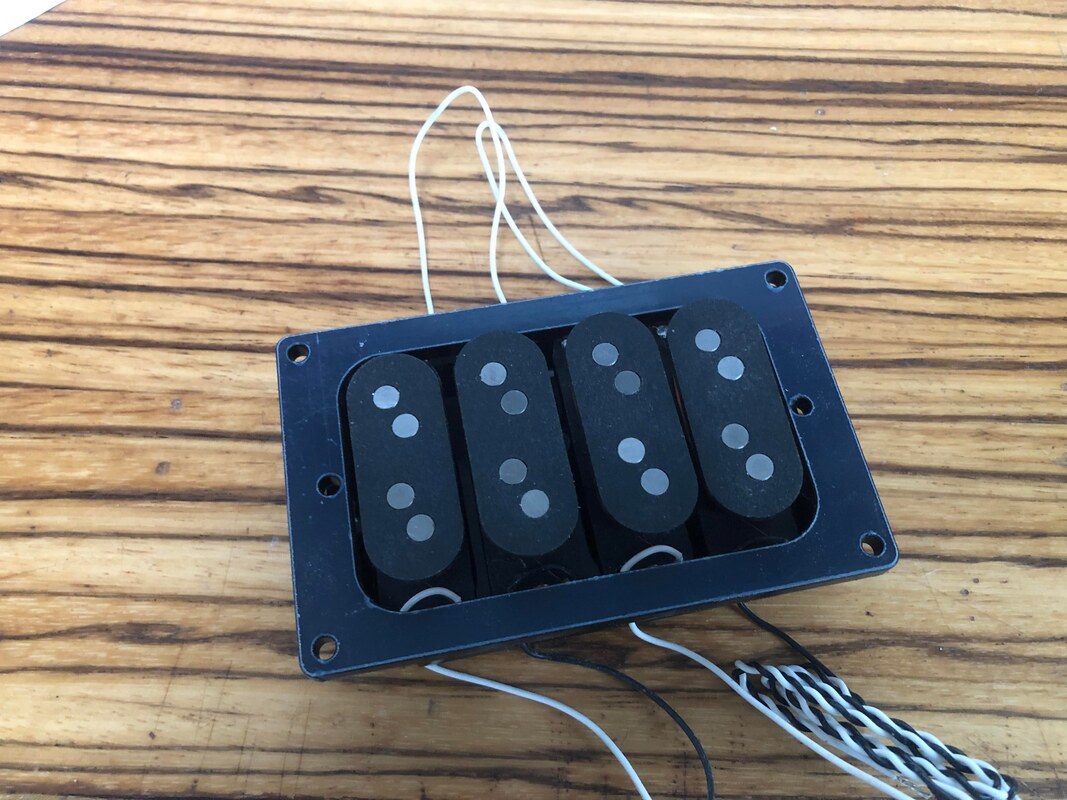

Same goes for the QuadBucker.

It consists of two Nordstrand NM4 pickups that are meant to be mounted on a Mustang bass.

I used them parallel to the strings instead of perpendicular to the strings.

Because of the staggered pole pieces they can pick up the amplitude of the three strings per triplet better than the original pickups that Hamer used (three in a row, under the middle of each triplet).

I designed base plates and a frame for the QuadBucker. And also a matching frame for the Lace Alumitone.

And I laser cut them too.

Initially I tried to use the NM4 with the casings over the pickups.

But eventually I chose not to use the casings, because I think this looks better without. 😉

-

3

3

-

-

A while ago I finished the build a a rather challenging bass build.

The Brooks QB.

This 34" scale twelve-string bass is a tribute to the Quad Bass that Jol Dantzig from Hamer built for Tom Petersson in 1978.

Except I didn't put a mixer in the built-in panel, but two effects!

A big thank you to Bas Becu from BQ Music for building the SansAmp type overdrive and the Aguilar TLC Compressor.

- Mahogany body. Les Paul Junior Double Cut shape

- Flamed Maple top. Sun burst high gloss

- Body back, sides and neck: Mahogany gloss

- Pearloid Binding

- Glued neck, mahogany/maple five piece laminate.

- Two spoke wheel type double action truss rods.

- One carbon stiffening rod.

- Ebony Fretboard. White side dot inlays

- Sintoms Jumbo frets. Nickel-silver

- 34” Scale

- Buffalo horn nut/ string guide

- Custom made 12 string bridge and tailpiece. Black

- 4 x Gotoh GB 350 bass tuners. Lightweight. Black

- 8 x Gotoh ST-31 Octave string tuners. Lightweight. Black

- D’Addario EXL 170-12 strings

- Gotoh large black strapnuts

- Pickup 1: Lace Alumitone. Black

- Pickup 2: 2x Nordstrand NM4

- 2 x Switchcraft output.

- 2 x Volume. On/off switch with led light for each effect

- Weight: 4,5 kg

I'm pretty sure the new owner is Gonna Raise Hell on this monster!

I'll post pics of the entire build process in separate posts below...-

16

16

-

-

4 hours ago, smithy said:

Wow -That´s an eye opener. What about some details? Looks like short scale?!

I did miss that Grabbird thread , and although I´m not really into the thunderbird design, I´m deeply impressed by that workmanship.

No, it's 34" scale.

I enlarged the EB-0 (LP Jr DC) body a bit to make the proportions fit the scale length. And to prevent neck dive.

You see the entire build proces here:

https://www.brooksbassguitars.com/brooks-eb-tb.html-

1

1

-

-

Thank you Roger. Nice to meet you here too.

And thank you Michael. I do realise I've been a bit lazy with my posts over here.

Haven't shared my latest builds...

Let me know if you think I should.

-

1

1

-

-

Not exactly a Fenderbird like Peter Cook made them. Part II

It's my take on the theme of a hybrid between a classic Gibson and a classic 7enderI call it a Thinline Telebird:

-

8

8

-

-

On 22/12/2022 at 13:23, nilorius said:

I won't and i don't call 8-12 string bass type instrument a normal bass guitar, no matter what and how it is played. Maybe - octopus music machine.

You probably don't realise it is played as regular 4 string. Except it has four triplets of strings. You hit the bass string plus two octave strings in one stroke.

-

1

1

-

-

Routed the neck pocket. Using the laser cut template

Shaped the heel to make it a good fit

Checked the angle

Before I glued the neck in, I drilled holes into the headstock

Then glued the neck into the pocket

Routed the pickup cavity

Checked if it fits.

And if it lines up properly

Drilled the string through body holes on the back side of the body

Taped of the fretboard. Getting ready to stain the body

Stained the back and sides a dark brown with a hint of red

Then stained the top a wine red / blood red

Scraped the binding clean. And sprayed the first layer of clear

Sprayed the headstock face black.

After many layers of clear and lots of sanding in between I put the decals in place

Made the custom pick guard per special request. The guy who ordered the guitar is a massive fan of the band Rush.

Used the laser cutter to engrave the Starman logo.

Then filled it with white acrylic paint.

-

10

10

-

-

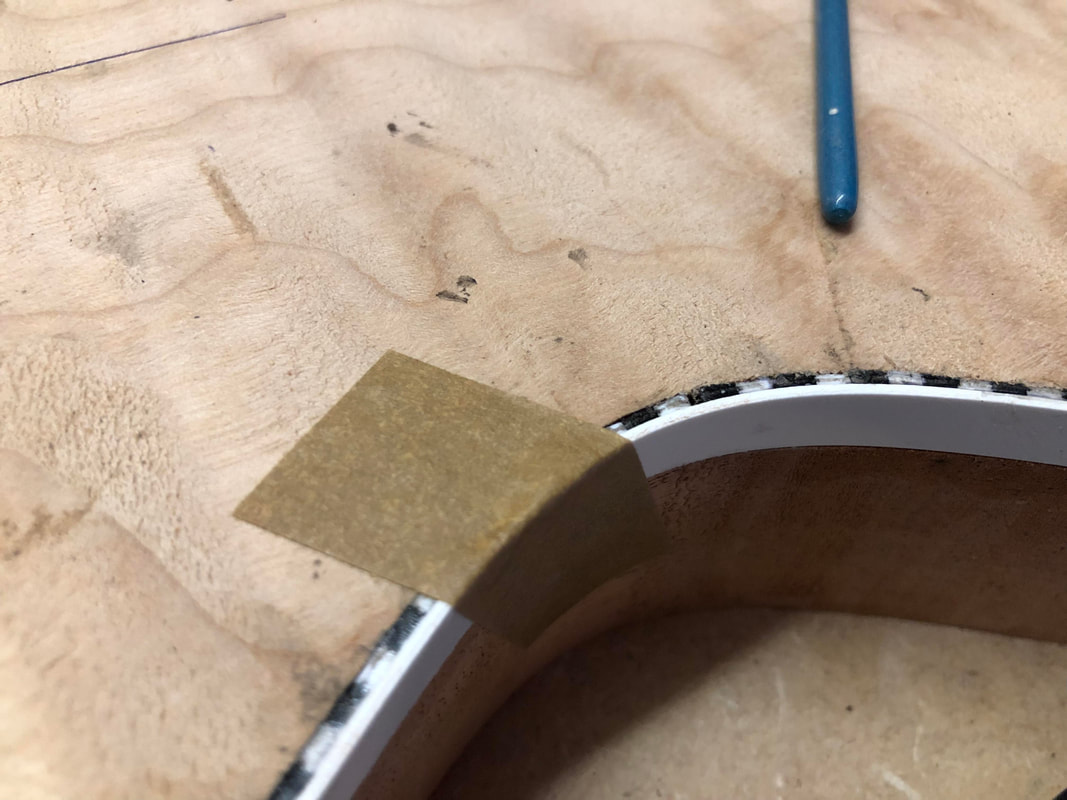

Glued in the strips of checkerboard binding. Using acetone instead of glue, in order to prevent glue spilling on the top or side.

Then routed the black strip off on the outside of the binding. Leaving just the clean black and white block pattern

Glued the outer (white) binding in place. Again using acetone

Scraped it clean

Back to the neck;

Drilled holes for the side dots

Glued the side markers in

For the 12th position I used the same method as the one on the fretboard

-

2

2

-

-

Fast forward to the neck.

Got no pics of routing the truss rod channel. And no pics of cutting the headstock angle. Nor trimming the neck to the right width.

Glued the fretboard onto the rough shaped neck

Left enough wood beyond the heel to allow for decent clamping onto the workbench.

Shaped the neck profile. Using a spoke shave and a coarse file. I should try a shinto rasp some day.

At my day job I have access to a laser cutter. I made vector files and cut out the templates for the body.

Prepared the slab for the body. Drilled a few holes with a forstner bit, to make it easier for the handheld router.

Routed the control cavity and the slot for the pickup wires

Glued the beautiful quilted maple top -that I scored at Holz Faszination- onto the body. You can never have too many clamps, right?

Routed the body shape along the laser cut template

Body outline ready

Routed the profile for the controls cover on the back

On the front side I routed the channel for the binding

-

3

3

-

-

I started with two nice slabs of Mahogany or actually it's called Khaya. It has a nice and even grain and it is very light weight.

I asked the timber supplier to make the neck blank a three piece for me. It saves me a lot of time.

For the 12th position inlay I use a tube of aluminium and cut off a ring.

Bought a pre-slotted ebony fretboard at Holz Faszination in Germany. Drilled holes. And glued then inlays in

The inside ring of the 12th inlay is exactly the size of a regular black inlay. So I just glued that dot in. I mixed the superglue with ebony sawdust, just in case there would be a gap

Then sanded the inlays level with a radius block. Sorry no pics. (forgot)

Taped off the fretboard to get ready for hammering the frets in. I fill each fret slot with a few drops of super glue./ The tape makes sure it doesn't splatter onto the fretboard

Cut off the excess on both sides

-

4

4

-

-

This week I completed the build of a guitar (yes, six string).

It is a hybrid of a Les Paul Junior Double Cut and a Tele (or actually Esquire).

The Brooks LP-TC Amalgamation

- Mahogany body

- Bookmatched Quilted Maple top

- Mahogany 3-piece set neck. Glued in

- Wine Red stain

- Ebony fretboard with abalone inlays

- Jumbo frets

- Checkerboard binding

- 24 3/4" scale

- Buffalo horn nut

- Telecaster style bridge. With compensated saddles. Black

- Double action spoke wheel truss rod

- DiMarzio The Chopper T (DP-384) humbucker

- Gotoh SG-381 locking tuners. Black

- Push-pull Volume knob for parallel-series switching

- 250k Tone knob

- Black knurled barrel knobs

- Mallory Mustard Tone capacitor

- Weight 3.25 kg

Serial number: 2022006

With a special Amalgamation logo on the headstock and Starman logo on the custom pick guard.

How does it sound?

Like this!

I'll post pics of the build process in separate posts below.

-

12

12

-

-

On 12/09/2022 at 18:14, warwickhunt said:

Indeed and I checked out his amazing work but going off comments on various sites/threads, we'd be talking easily in excess of £3-4k.

Not saying his work isn't worth that, it is but am I going to max my budget out on this project... I doubt it.

More like £2750 - 3250. Depends on the specs really. If you don't want a fancy flamed or quilted top and no weird finish you could stay on the lower side.

Show us your sunbursts

in Gear Gallery

Posted

Nope. It's 34"scale