-

Posts

388 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Shop

Articles

Posts posted by alittlebitrobot

-

-

2 hours ago, ped said:

You guys seen this? Fender Japan are doing a signature Mustang with JJ configuration pickups

https://www.soundhouse.co.jp/en/products/detail/item/370161/

Ridiculous. I made a JJ Mustang from a Bronco for less than half that price. Ok, the MIJ one has better pickups, hardware, electronics and general workmanship, but apart from that..

-

8

8

-

-

1 hour ago, AndyTheBassBison said:

Excellent 👌 I love a matching headstock. What's the story with that pickup?

-

1

1

-

-

1 hour ago, tauzero said:

Headstock looks like a Reverend one chopped off at the end.

This is why headless basses are the future.

True, but it's a slippery slope. It's only a matter of time before somebody chops the first fret off.

-

1

1

-

2

2

-

-

For me, this is so much more balanced and aesthetically pleasing than a Rickenbacker, though, and plenty of people love those things, so I do think there's an audience for the Scout. ...but not in this thread 😁

Poor Scout.

-

1

1

-

1

1

-

-

I have a 5 string version of the first one you linked to, but that project is as yet unfinished so I don't know if it's any good. But, to @Richard R and @Huge Hands question about turning the wheels under tension; each wheel has a hex socket so can theoretically be turned with the mini hex it comes with. I'll be interested myself to see how the theory holds up in practice.

I also have a 4 string OVERLORD OF MUSIC one from a now-disassembled bass I made. It was much improved by the addition of thrust bearings, but the end of the tuners are now a good 90mm from the rough scale line.

-

2

2

-

-

That is weird as hell and I love it.

Actually, there is one thing I hate about it and that's the tortoiseshell guard. Big fan of everything else.

-

2

2

-

-

I suppose one of the issues is that they keep making them. If people in the 90s were looking for 60s-era basses then that's the equivalent of looking at basses from the 80s today, and there's plenty of them knocking about.

-

1

1

-

-

1 hour ago, Joe Nation said:

That's so odd, almost looks as if the router template got broken and they bodged it with some filler.

I know! But look it up. Any photo you find of a Bronco has this exact shape. It's infuriating 😆 Happy I sorted mine, though.

-

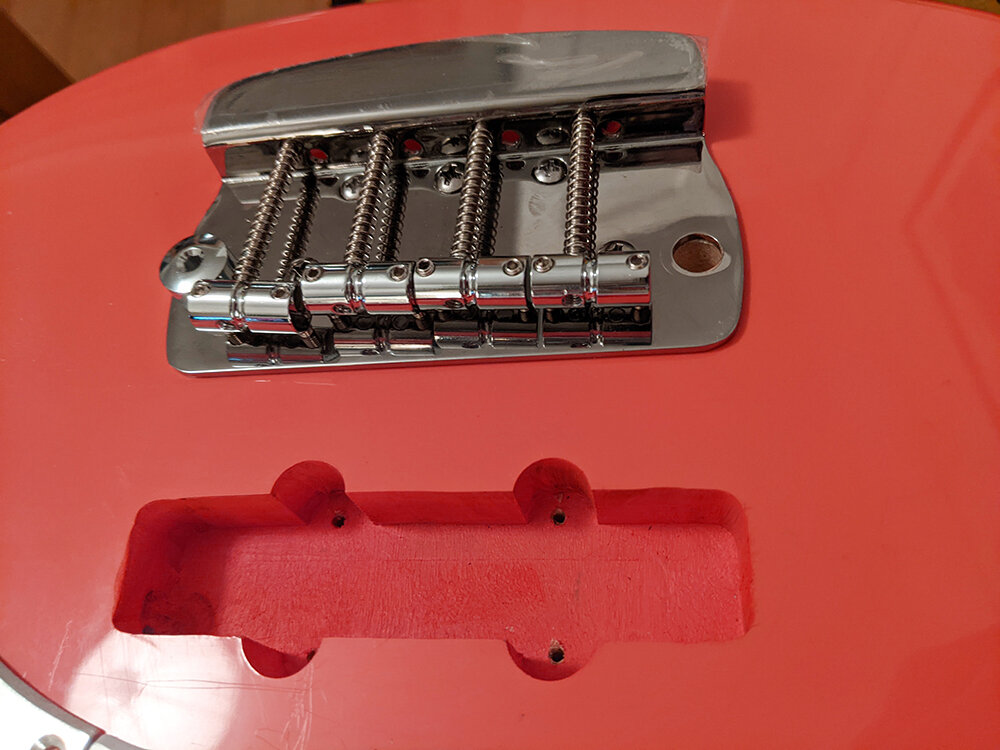

Bought a Bronco recently. Modified it. Now it looks like this

Brief project diary HERE for the curious.

-

9

9

-

-

Stunning @ped Love the p'up cover colour too

-

1

1

-

-

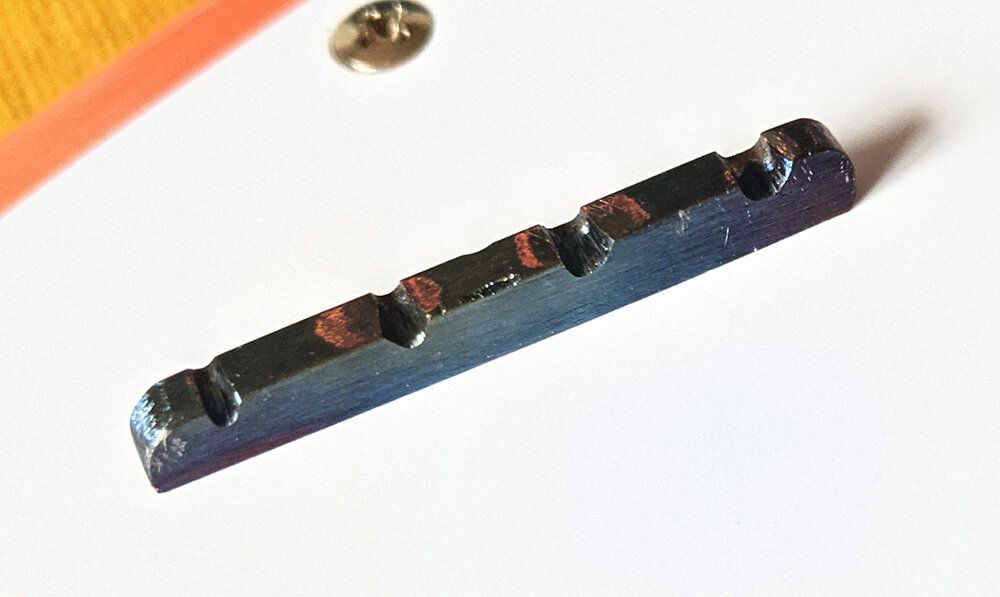

skip to the end, and here it is! (except this is with the nut in it's 'still pretending to be brass' state)

The pots are the original ones that came with the bass. A pair of 250k pots which I've wired as volume - tone - 3 way selector switch.

If there's any electronics boffins reading, can you help me with something? The bass had a .22 capacitor, but I replaced that with a .47 one. The only thing is, the tone pot has *basically* no effect. It's not absolutely zero, in which case, I could just assume the pot isn't doing anything, but it's just slightly more than zero. There is an absolutely miniscule difference between fully open and fully closed. Capacitor problem? Pot problem? Something else?

Anyway, despite the lack of tonal variety, the sound is much-improved from the stock Bronco.

EDIT: The tone pot works now! Turns out the capacitor was dodgy. Sounds great now. Very happy

-

6

6

-

-

Now, the headstock of the Bronco drives me up the wall. When I was looking at the photo I'd dragged into Photoshop, I assumed there was some kind of glitch or maybe just something weird with that specific bass. Then my real one arrived and it had the same thing. There's a weirdly-awkward curve to the bottom edge where it goes kinda straight between the D and G tuner., so I brought it to the belt sander to sort it. Here's a fade between the stock shape and my alteration.

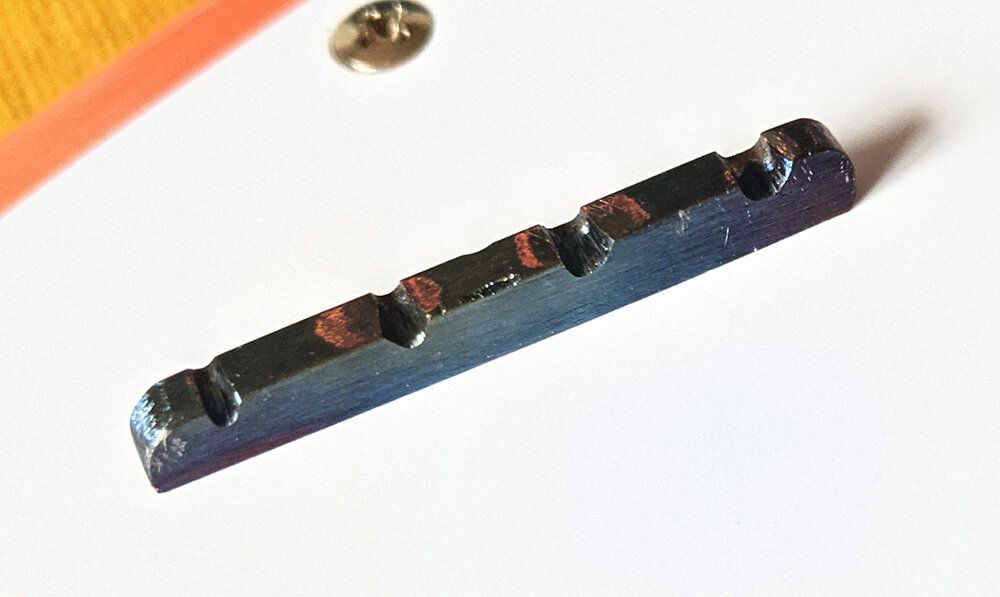

The bass comes with a plastic nut, but I had a "brass" nut in my shoebox that was the right width E-G but slightly too thick, so I routed a groove in some mdf, stuck the "brass" nut in there and brought it to the sander until it was the correct thickness. This process caused the brass to fall off what was actually some other metal, so I blowtorched it until it went black and blue and purple in a fun way.

Having routed the bridge pickup cavity and caused a paint chip at the E string entry point, I got my acrylics out and mixed up some Tahitian Coral. This turns out to be mostly red, some white, and then some yellow to taste.

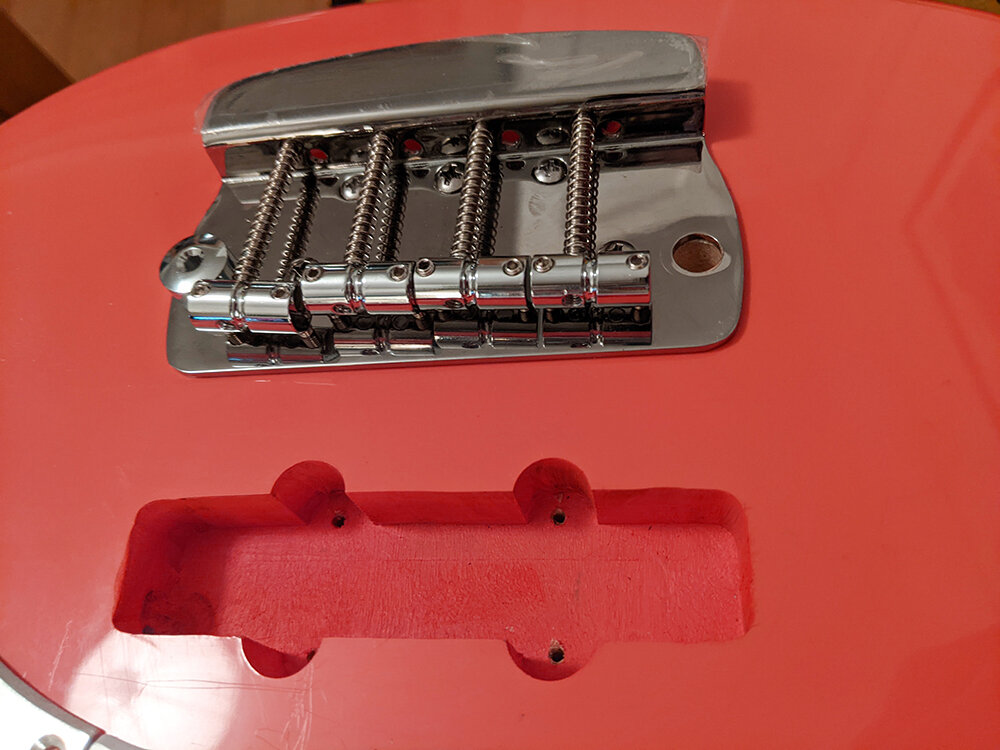

The bridge comes with these whopping 12mm threaded inserts but this is overkill tbh, because I've already got five screws in the thing. However, I like the look of these little doohickeys so, rather than drill two deep holes in the body, I just drilled enough for the bolts to stick into, with a wee dab of glue to keep them in place.

-

1

1

-

-

34 minutes ago, ped said:

Cool project ( I’ve just finished a J/J Musicmaster). Re the strings, can’t you bend tapewounds around the post enough, or cut them? I can’t say I’ve ever really used them. I assume the control layout is VVT?

I wanted to completely sure the silks wouldn't sit on the saddle and I don't feel like tapewounds can be cut or bent super-tight. The controls are volume, master tone and a three-way switch.

-

1

1

-

-

I won't bother explaining it but I went about the pickguard in the wrong order and binned my first attempt. Luckily the sheet of plastic was big enough to get two out of it, so this is the second version. The metal control plate went well but aluminium gets so gummy when cutting or sanding. So, for the record, I cut out the silhouette of the pickguard, refined it on the belt sander and then scraped the 45 deg bevel with a utility knife. I then drilled the screwholes and screwed it in place before marking out the pickup hole so it was definitely perpendicular to the strings in the end. This also meant that I could later use the neck pocket as a routing template with a bottom bearing bit.

right, E string time. I drew what I guessed was an angle similar to the break angle of the bridge. I don't think tapewound strings can take a 90 degree bend. That's not something I've tested - I may be dead wrong - but they just feel like they shouldn't be bent that severely.

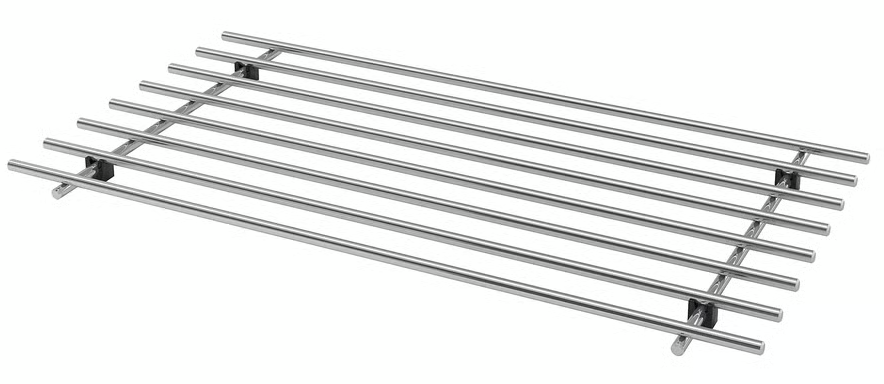

I have a disassembled LÄMPLIG trivet from IKEA that comes in handy around the workshop. In this case, it forms a metal lining for the 'tunnel' and won't let the ball-end pass through.

Oops. Chipped the paint. Surprisingly fragile. After this photo, I hammered it in enough so that the ball-end of the string is within the body.

Oh look, @Burns-bass has one for sale right now, and willing to post! Somebody get on that, toute suite.

-

1

1

-

-

My taste in bass design has always been for the more modern styles but, for some reason, I've recently been drawn to the Fender Mustang. In particular the JMJ model. Literally zero chance of me ever buying one but it did mean that I found out about the Bronco, which I also liked the look of. The other things I liked the look of was the Tahitian Coral paint job, the maple fretboard and the price tag, so I was keeping an eye out for a few months until I saw one come up online, discounted as "B-stock". When it arrived it was pristine, so I'm guessing it was a return or something. Happy days.

I immediately loved the weight of it and the shape of the neck. The fret job was spot on too. Nothing to complain about except that putting a cheap 6 pole strat single coil on a bass is just unacceptable. The tone wasn't horrendous, but it wasn't much good either, so I set about planning some modifications. From what I've seen online, replacing the cheap single coil with a more expensive one is the most common mod to this bass, and the next most common seems to be replacing it with a P pickup. My issue is that I don't like the tone of a P bass so I decided to go for double J because I have a set of J p'ups in my shoebox of bass parts and that's the key to this project; keep it simple, quick and as cheap as possible. I have a 2 year old and a part-time job - spare time for bass-modding is minimal.

So, let's start with the stock model, followed by my Photoshop mock-up, incorporating the Mustang-style pickguard shape with metal control plate. I want to use nylon tapewound strings because I love nylon tapewound strings, but I don't want to have to source short scale versions, so I need to extend the E string by making it through-body so I'll need to drill a hole behind the bridge. Luckily some Mustangs have that bridge with the wee overhang at the back end, so that'll hide the hole and look the part.

Budget-wise; I needed to buy that bridge, replacement white p'up covers, some pickguard material and a small rectangle of 3mm aluminium. Oh, and the strings but they were second-hand.

I'm writing this all after finishing the job, but I'm going to break up my posts anyway.

-

4

4

-

-

Oh wow, that's a strong flavour. Not my taste but I do love a bold statement. Enjoy!

-

1

1

-

-

There's obviously no right answer, but Bakithi uses rounds, so I use rounds.

-

16 minutes ago, ped said:

Once it’s done it’ll be blend/tone with a series/parallel switch on the tone pot. I’ll probably favour the bridge pickup on the fretless so it’s good that the DiMarzio J pickups are hum cancelling. I wanted to keep the jack on the front of the bass to match the Mustang but three pots is also a good option 👍🏼Yeah, I agree - I'm reshaping the pickguard and will probably have to rout the cavity a wee bit so I think I can fit three pots while keeping the input jack where it is. I'm just not convinced about the VVT approach. I'd like to have some blend so I'm exploring my options now.

-

1

1

-

-

On 12/09/2025 at 10:03, ped said:

Welcome to BC @DanDoesBass

I'm a paid up member of the Mustang Brotherhood - which is weird, because a few years ago I would have laughed at the idea. I bought the '66 Mustang on a whim and fell in love with it, especially with rounds. Since I had it modified with new pickups it's become my favourite bass. I realised that short scale would be really well suited for fretless, given the additional weight afforded to the higher strings. I bought the '72 Musicmaster and a fretless Mustang neck to test that idea, and it's fantastic. Shortly the bass is going to a local luthier who is doing a few other bits such as correcting the electronics, replacing the bridge and possibly epoxy coating the board.

Beautiful combo!

I just bought a squire Bronco and I'm replacing the stock p'up with two jazz pickups like yours. I was going to go for full-fat jazz bass wiring (volume, volume, tone) but I see you've just got two pots. What's the wiring setup?

-

1

1

-

-

With orders coming in thick and fast and companies bending (their employees) over backwards to deliver your order the very same day or sooner, it's bound to happen. The thing is how they deal with it. They once sent me my order of 4-5 small to medium sized items, and everything was there, except there was also a 4 pack of Vic Firth drumsticks. Maybe one of the staff was just feeling generous. [insert Oprah Winfrey meme "and YOU get drumsticks, and YOU get drumsticks!.."]

-

1

1

-

-

Hi @deadshed

Buying from the UK has become fairly nightmarish post-Brexit. The cost of postage in both directions is insane and then there's customs. I occassionally buy and sell in the classifieds section here - if I'm selling, I go across the border and post from Newry to avoid the other stuff but when it comes to buying, I have to include a hefty mark-up postage and customs markup in my budget when it comes to buying from other BC'ers. An Post have a thing called Address Pal that gives you a virtual UK address, so that reduces the cost of postage to the seller, but it's not way of bypassing the other costs to yourself.

Adverts and DoneDeal are the best place to buy second-hand and, in my experience, Gear4Music are the best option for new (or B-stock) gear because they're fulfilled from Ireland so the postage is cheap and there's no import.

Anyway, welcome

(where's NA?)

-

Yeah, another vote for keeping the thin pink line. This is coming together so nicely.

-

Could you post the measurements whenever you get a chance, please?

-

1

1

-

-

Haven't done one of these for a year (or two?), I'd love to give this a go if I can find the time.

Casady Fretless

in Bass Guitars

Posted

No you may not! That is a beautiful bass.